About AAR Circular Letters

Circular letter summaries are produced monthly by Greenbrier’s Regulatory Management team, a division of Greenbrier Management Services Group.

AAR circular letters provide information of general applicability to the railroad industry, including proposed and final rules, revisions, standards and recommended practices, and calls for comments. These summaries provide the main points of circular letters issued in the prior month, as well as important implementation deadlines.

For access to the complete circular letter, please go to my.aar.org/circulars. Circular letters are a fee-based service provided by the AAR’s Transportation Technology Center Incorporated (TTCI). You may subscribe online at publications@aar.com or call 719.584.0538.

C-12803

Implementation of Revisions: Figure 43-T– Section 2 AAR Open Top Loading Rules Manual (OTLR)

Issued: February 01, 2017

Effective: February 01, 2017

The changes to this figure added “stake pockets” as a not to secure web tie-down straps for Item. The description for Item E now reads:

“Web tie-down straps: polyester webbing, 4 in. wide with a minimum breaking strength (MBS) of 20,000 lb. Pass strapping over all ingots in a pile, pass under load and back across the top of the load, and secure to the winch or stake pockets on each side of car. Tension straps from both sides of car using a 30 to 40 in. winch bar or equivalent. Type 1A, Grade 8 polyester strapping may be substituted for 4 in. webbing.”

The implementation of this revision to Section 2 is effective immediately and will be included in the next edition of the AAR’s OTLR Manual. In the interim, please insert the circular attachment for Figure 43-T in your copy Section 2 and be governed accordingly.

C-12804

Implementation of Revisions to Figures 58-B and 58-C– Section 5 AAR Open Top Loading Rules Manual (OTLR)

Issued: February 01, 2017

Effective February 01, 2017

The AAR’s Open Top Loading Rules Committee (OTLRC) has approved revisions to Figure 58-B and new figure 58-C, RAILROAD TIES, TREATED OR UNTREATED, PACKAGED, 8-FT LONG AND OVER— FLATCARS WITH CENTER A-FRAME, PERMANENT END BULKHEADS, CUSHIONING DEVICES, AND CABLE TIE-DOWN SYSTEM – Section 5 of the AAR Open Top Loading Rules.

The changes to 58-B add a new note to state: “Void, if any, must be centered and not exceed 18 in.”

Also, Note 4 was replaced with the following: “No incomplete layers allowed. All packages in a layer must be of equal height.

The implementation of this revision to Section 5 is effective immediately and will be included in the next edition of the AAR’s OTLR Manual. In the interim, please insert the circular attachment for Figure 58-B and 58-C in your copy Section 5 and be governed accordingly.

C-12805

Implementation of Revisions to Figure 113– Section 5 AAR Open Top Loading Rules Manual (OTLR)

Issued: February 01, 2017

Effective:

The AAR’s Open Top Loading Rules Committee (OTLRC) has approved revisions to Figure 113– Section 5 of the AAR Open Top Loading Rules.

The changes to this figure add the following to the description of Item E (No. of Pieces): “As Required. 2 per each package 18′ long. Add 1 for each additional 20′ long or less.”

The implementation of this revision to Section 5 is effective immediately and will be included in the next edition of the AAR’s OTLR Manual. In the interim, please insert the circular attachment for Figure 113 in your copy Section 5 and be governed accordingly.

C-12806

Implementation of New Figure 27, Section 5 AAR Open Top Loading Rules Manual (OTLR)

Issued: February 01, 2017

Effective: February 01, 2017

The OTLRC requested comments from the industry regarding the implementation of New Figure 27, Section 5 AAR Open Top Loading Rules. The comments from the industry have been considered and the AAR Open Top Loading Rules Committee (OTLRC) has approved the implementation of Section 5 of the AAR “Open Top Loading Rules.”

The implementation of this revision to Section 5 is effective immediately and will be included in the next edition of the AAR’s OTLR Manual. In the interim, please insert the circular attachment for Figure 27 in your copy Section 5 and be governed accordingly.

C-12807

Implementation of revision to Attachment C1, Section 1 Open Top Loading Rules- OTLRC

Issued: February 01, 2017

Effective:

The Open Top Loading Rules Committee (OTLRC) has approved revisions to Attachment C1, Section 1 Open Top Loading Rules. The words “die cut” have been removed. The revision has been made to require flex testing for all sealless steel strap joints.

The implementation of this revision to General Rules Attachment C1 is effective immediately and will be available for download at http://www.aar.com/standards/OpenTop-approvals.html.

Carriers are asked to ensure that copies of this circular letter are distributed to all concerned shippers and railroad personnel for their attention and guidance.

C-12808

Implementation of revision to General Rules 3.5.2 to Address Floor Contact between the Load and the Floor on Centerbeam Cars Equipped with Risers- OTLRC

Issued: February 02, 2017

Effective: February 02, 2017

The Open Top Loading Rules Committee (OTLRC) has approved revisions to General Rules 3.5.2.

General Rule 3.5.2.1 will be added and will state:

3.5.2.1 On centerbeam railcars equipped with steel risers, no part of the load shall contact the car floor between risers.

The implementation of General Rules 3.5.2.1 is effective immediately and will be available for download at: http://www.aar.com/standards/OpenTop-approvals.html.

C-12809

Implementation of revision to General Rules 5.2.1 to Address the Definition of an Eccentrically Loaded Weld- OTLRC

Issued: February 02, 2017

Effective: February 02, 2017

The Open Top Loading Rules Committee (OTLRC) has approved revisions to General Rules 5.2.1.

The rule currently states:

5.2.1 Floor blocking must be attached to a sound floor free from defects that could hinder solid application of securement. For maximum restraint, all fasteners must be perpendicular, or at 90° to the floor, because by definition, floor blocking is designed for lateral and longitudinal restraint. If plate welded to the car is used for floor blocking, provide a vertical component by adding a lip or catch to the securement to prevent any vertical movement. The lip is parallel to the car floor. Provide filler as needed for solid or full contact. When plate welded to the car floor is used for blocking it shall consist of two pieces, one placed flat against the load (vertically) and welded to the car floor along with a backup piece placed perpendicular to the 1st piece. When the plane of the load does not act through the weld (eccentrically loaded weld), the length of the floor weld must be 2 ½ times the height of the point of contact between first piece and load.

The rule will now state:

5.2.1 Floor blocking must be attached to a sound floor free from defects that could hinder solid application of securement. For maximum restraint, all fasteners must be perpendicular, or at 90° to the floor, because by definition, floor blocking is designed for lateral and longitudinal restraint. If plate welded to the car is used for floor blocking, provide a vertical component by adding a lip or catch to the securement to prevent any vertical movement. The lip is parallel to the car floor. Provide filler as needed for solid or full contact. When plate welded to the car floor is used for blocking it shall consist of two pieces, one placed flat against the load (vertically) and welded to the car floor along with a backup piece placed perpendicular to the 1st piece. When the plane of the load does not act through the weld (eccentrically loaded weld), the length of the floor weld must be 2 ½ times the height of the point of contact between first piece and load. Any load in which the first vertical point of contact is over 1” above railcar floor is considered an eccentrically loaded weld.

The implementation of General Rules 5.2.1 is effective immediately and will be available for download at http://www.aar.com/standards/OpenTop-approvals.html.

C-12810

Implementation of revision to General Rule 19.5.1 to add the requirement of printing Grade # and MBS on Type 1A nonmetallic strapping- OTLRC

Issued: February 02, 2017

Effective: February 02, 2017

The Open Top Loading Rules Committee (OTLRC) has requested comments from the industry regarding the proposed requirement of printing Grade # and the ASTM Minimum Breaking Strength (MBS) in pounds to Type 1A nonmetallic strapping in addition to the AAR ID number. Those comments have been considered and the Open Top Loading Rules Committee (OTLRC) has approved a revision to General Rule 19.5.1 Section 1 AAR Open Top Loading Rules. The OTLRC is granting suppliers one year to comply with the revision to General Rule 19.5.1.

The rule currently states:

19.5.1 All approved nonmetallic strapping must be marked with the letters “AAR” followed by the AAR-assigned identification mark.

The Revision to this rule will include the requirement of Grade and MBS (in pounds) for all Type 1A nonmetallic strapping and shall be stated as:

19.5.1 All approved nonmetallic strapping must be marked with the letters “AAR” followed by the AAR-assigned identification mark, strap grade and MBS. Example: “AAR 123 Grade 7 MBS 11,000 lbs”

Minimum breaking strength (MBS) is defined as: In a straight pull test, “The minimum load at which the securement, component, or assembly has been found by representative testing to fail when a constantly increasing force is applied in direct tension. This is also referred to as demonstrated breaking force or ultimate load. This is a manufacturer’s statistical attribute acceptance test; usually stated in pounds.”

The implementation of this revision to General Rule 19.5.1 is effective immediately and will be available for download at: http://www.aar.com/standards/OpenTop-approvals.html.

C-12811

Implementation of revision to General Rules 21.10.5, 21.10.11 and 21.11.10 to Address the Securement of Unused and/or Slack Chains and Chain Grade- OTLRC

Issued: February 02, 2017

Effective: February 02, 2017

The Open Top Loading Rules Committee (OTLRC) has approved revisions to General Rules 21.10.5 and 21.11.10.

The rules currently state:

21.10.5 Whenever practical, all available car chains should be used. Unused chains must be securely fastened to prevent displacement over the car side, presenting a potential hazard.

21.10.11 Chain and chain tie-down assemblies, dimensions, and minimum breaking strengths are shown in Appendix D, paragraph 4.7. See Table 21.4 for approved chain manufacturers and methods of identification.

21.11.10 All unused chain tie-down assemblies must be securely positioned to eliminate the possibility of displacement over the car side, presenting a potential hazard.

The revised rules will state:

21.10.5 Whenever practical, all available car chains should be used. All unused and/or slack chains must be secured to prevent displacement over the car sides, car ends, through holes in car floor, or through holes in chains channels and stake pockets, presenting a potential hazard.

21.10.11 Chain and chain tie-down assemblies, dimensions, and minimum breaking strengths are shown in Appendix D, paragraph 4.7. See Table 21.4 for approved chain manufacturers and methods of identification. See table 21.5 for a summary of chain grade, size and MBS.

21.11.10 All unused chain tie-down assemblies must be securely positioned to eliminate the possibility of displacement over the car sides, car ends, through holes in car floor, or through holes in chains channels and stake pockets, presenting a potential hazard.

Table 21.5 was added.

The implementation of these revisions to General Rules 21.10.5 and 21.11.10 are effective immediately and will be available for download at http://www.aar.com/standards/OpenTop-approvals.html

C-12812

Implementation of the Addition of Table VI to Appendix D, Section 1 Open Top Loading Rules- OTLRC

Issued: February 02, 2017

Effective: February 02, 2017

The Open Top Loading Rules Committee (OTLRC) has approved the addition of Table VI in Appendix D, Section 1 Open Top Loading Rules. This table provides information regarding Special Alloy Chain.

The implementation of this revision to Appendix D, Section 1 is effective immediately and will be available for download at http://www.aar.com/standards/OpenTop-approvals.html.

C-12813

Implementation to Archive Figure 123, Section 2, AAR OPEN TOP LOADING RULES MANUAL

Issued: February 02, 2017

Effective: February 02, 2017

In accordance with the requirements of AAR Standard S-050, the OTLR Committee has approved the archiving of Figure 123 from Section 2 due to non-use.

Figure 123, Section 2, Pipe, Steel, 26 in. O.D. and Less, Uniform or Mixed Lengths and Diameters, with Wire, NO. 3 Gauge High Tension – Gondolas will be archived into the AAR Open Top Loading Rule Manual Section 4 2016 Revision.

Section 4 addresses the Archiving of Rules and Figures from Sections 1 through 7. Figures in this New Section 4 have been withdrawn by the Open Top Loading Rules Committee from their original Section for various reasons, such as unsafe loading method, no longer applicable due to car structure, etc. These archived figures are no longer intended for publication unless re-instated by the Open Top Loading Rules Committee

These changes are effective immediately and will be included in the next edition of the AAR’s OTLR Manuals. In the interim, please print or copy for your records until the new Section 4 is published

C-12814

Implementation of Revisions to Figures 29-D, 29-H, 29-L and 29-M– Section 2 AAR Open Top Loading Rules Manual (OTLR)

Issued: February 02, 2017

Effective: February 02, 2017

The AAR’s Open Top Loading Rules Committee (OTLRC) has approved revisions to Figure 29-D, 29-H, 29-L and 29-M, Section 2 of the AAR Open Top Loading Rules.

The changes to this figure corrected the angle depicted in the drawings. The documents attached to the circular show the correct orientation of the trough engagement and coil diameter.

The implementation of this revision to Section 2 is effective immediately and will be included in the next edition of the AAR’s OTLR Manual. In the interim, please insert the circular attachment for Figures 29-D, 29-H, 29-L and 29-M in your copy Section 2 and be governed accordingly.

C-12815

Implementation of revisions to Figure 40 SHINGLES, PALLETIZED, MINIMUM 40 IN. × 40 IN.—RISERLESS CENTER A-FRAME FLATCARS – Section 5 AAR Open Top Loading Rules Manual (OTLR)

Issued: February 02, 2017

Effective: February 02, 2017

The AAR’s Open Top Loading Rules Committee (OTLRC) has approved the Implementation New Figure 40 SHINGLES, PALLETIZED, MINIMUM 40 IN. × 40 IN.—RISERLESS CENTER A-FRAME FLATCARS – Section 5 AAR Open Top Loading Rules Manual (OTLR).

The number of pieces required for Item D was changed to “As required.”

The sentence “Bags may not be used in tandem (inflated-face to inflated-face)” was added to the end of note 7.

Note 8 was added:

When it is not possible to get two cables over each package on both sides of the centerbeam, Type 1A Grade 7 encircling bands may be used to encircle all packages on both sides of the centerbeam.

The implementation of these changes to Figure 40, Section 5 is effective immediately and will be included in the next edition of the AAR’s OTLR Manual. In the interim, please insert the circular attachment for Figure 40 in your copy Section 5 and be governed accordingly.

C-12816

Solicitation of Comments on proposed new Specification, MSRP Section D, TRUCKS AND TRUCK DETAILS, New Specification M-980, Friction Wedge Performance for Railcars, Dynamic Wear Test

Issued: February 02, 2017

Effective:

The AAR Equipment Engineering Committee (EEC) is proposing a new specification for the approval of friction wedges through testing of the friction wedge material.

In order to comply with this specification, every wedge design, both existing and new, and from each foundry that a particular design is produced, must be approved by the Equipment Engineering Committee before continuing or being placed in interchange freight service. As currently written, the deadline for compliance would be one year after implementation of the specification. In addition to initial approval, the proposal includes a requirement to reapprove on a three-year interval.

A test fixture has been designed in order to conduct the test. The design requirements are included in the Specification.

A draft of proposed specification M-980 is attached. Comments from interested parties are herewith solicited under the provisions of AAR Standard S-050. All comments received within 30 days of the issuance of this circular will be considered by the EEC. Please submit comments to Jon Hannafious, Senior Manager, Equipment Engineering Committee at TTCI, at jon_hannafious@aar.com.

C-12817

Implementation of revision to General Rules 15.2.1 and 15.2.2 to Address the Application of Power Driven Nails- OTLRC

Issued: February 02, 2017

Effective: February 02, 2017

The Open Top Loading Rules Committee (OTLRC) has approved revisions to General Rules 15.2.1 and 15.2.2.

The rules currently state:

15.2.1 Power-driven nails and/or staples may be used, but the number specified in the applicable figure must be increased by one-third. The approved size substitution is listed in Table 15.2. In Appendix D, Table D.5, provides shear yield values by relative size.

15.2.2 Power-driven nails and/or staples may be used in a General Rules load. However, the number of nails must be double the quantity of conventional hand-driven nails. Reference Table 11.2, and double the number required for the stated width and length.

The rules will now state:

15.2.1 Power-driven nails and/or staples may be used, but the number specified in the applicable figure must be increased by one-third. Not applicable to chock blocks which are secured to bearing pieces and separators. The approved size substitution is listed in Table 15.2. In Appendix D, Table D.5, provides shear yield values by relative size.

15.2.2 Power-driven nails and/or staples may be used in a General Rules load. However, the number of nails must be double the quantity of conventional hand-driven nails. Not applicable to chock blocks which are secured to bearing pieces and separators. Reference Table 11.2, and double the number required for the stated width and length.

The implementation of the revisions to General Rules 15.2.1 and 15.2.2 are effective immediately and will be available for download at http://www.aar.com/standards/OpenTop-approvals.html.

C-12818

Implementation of Editorial Revisions to MSRP Section D, TRUCKS AND TRUCK DETAILS, Specification M-948, Truck Side Bearing

Issued: February 02, 2017

Effective: February 02, 2017

The AAR Equipment Engineering Committee (EEC) has agreed to editorial revisions of MSRP Section D, TRUCKS AND TRUCK DETAILS, Specification M-948 Truck Side Bearing. The standard lacked direction for approval of short travel side bearings. This was remedied by changes to paragraph 2.4 which describes the side bearing travel, and paragraph 3.1.2.4 which includes the fatigue cycle schedule. Both edits are highlighted by change bars.

The revised M-948 is attached to the circular. Changes are implemented effective immediately.

C-12819

Empty Car Center-of-Gravity (CG) Values in Umler: Request for Review and Correction

Issued: February 02, 2017

Effective:

Subject: Empty Car Center-of-Gravity (CG) Values in Umler: Request for Review and Correction

The purpose of this circular is to notify the rail industry that the AAR is requesting car owners to verify values entered in the Umler field “A045 – Center of Gravity Empty” for boxcars, flatcars, and certain gondolas, and that AAR will be contacting car owners who have questionable values in the field.

It has come to the attention of the AAR that there are questionable values for boxcars entered in Umler field “A045 – Center of Gravity Empty”. Upon closer look, values were found that were not realistic, including a number of cars with the CG field apparently transposed with the platform height. Use of incorrect values when determining loaded CG can result in unsafe loading scenarios.

Path Forward: To help remedy the situation, the AAR will review the Empty CG values for all boxcars. When a value below 50 inches and above 70 inches is found, car owners will be notified and asked to check for accuracy. The AAR may work to tighten the window for the boxcar query, as well as research the other car types that may be in need of correction. If questionable values are found in Umler for flat cars and gondola cars, future direction may be provided for these car types also.

CPC-1324

Solicitation of Comments on Proposed Revision to MSRP Section C Part III, M-1002, Specifications for Tank Cars, Chapter 2

Issued: February 03, 2017

Effective:

The Tank Car Committee (TCC) is requesting comments on provisions affecting Chapter 2 of the AAR Manual of Standards and Recommended Practices (MSRP), Section C, Part III, Specifications for Tank Cars (M-1002). These revisions address requirements for free interchange tank cars used for the transportation of materials toxic-by-inhalation (“TIH”) products.

The TCC is considering provisions addressing the timeframe for requiring the transportation of TIH material in the package specified in 49 CFR 179.102-3 for cars marked “DOT” and in TP-14877, paragraph 10.5.1.2, for cars marked “TC.” This activity will supersede CPC-1187 dated March 31, 2008.

2.8 Tank Cars Transporting TIH

2.8.1 After July 1, 2023, all tank cars used to transport products classified as TIH must comply with the requirements for tank cars built on or after March 16, 2009 (see 49 CFR 173.244 (a)(2), 173.314 (c) Note (12), 179.16 (c)(1), and 179.102-3 for cars marked DOT, or TP-14877 paragraph 10.5.1.2 for cars marked TC).

2.8.2 After July 1, 2019, all tank cars used to transport products classified as TIH, manufactured from carbon steel plate, must have tank heads and shells constructed of normalized material.

The following CPCs relate to this single effort:

CPC-1187 – Change to the Implementation of the AAR Standard for Tank Cars Transporting Toxic Inhalation Hazard Commodities; and

CPC-1184 – AAR Requirements for Tank Cars in Toxic Inhalation Hazard Commodity Service

To facilitate the handling of industry comments on CPCs, AAR requires Exhibit PC-1 form to be completed and furnished, via e-mail, to Matt Forister, Director of Tank Car Safety, at mforister@aar.org, within 30 days from the date of this circular.

Comments will be considered by the Tank Car Committee prior to taking final action.

C-12820

IMPLEMENTATION – Revision to MSRP Section H, JOURNAL BEARINGS AND LUBRICATION, Specification M-924, Adapter Finish

Issued: February 08, 2017

Effective: February 08, 2017

Comment Circular C-12720 was issued 10/02/2016 soliciting comments for proposed revisions to MSRP Section H, JOURNAL BEARINGS AND LUBRICATION, Specification M-924 Journal Roller Bearing Adapters for Freight Cars, concerning adapter finish and update to Appendix D, Manufacturers’ Trademarks.

No comments were received for the proposed revisions to M-924. This circular letter is for implementation of the revised M-924.

The attachment to this Circular contains the following replacement pages:

H [M-924] 1-58

These revisions to the Manual of Standards and Recommended Practices, Section H, JOURNAL BEARINGS AND LUBRICATION are now implemented effective immediately. Please update your library and be governed accordingly.

C-12821

IMPLEMENTATION – Revision to MSRP Section G, WHEELS AND AXLES, Specification M-101, Facility Inspections, and Specification M-107/M-208, Microcleanliness and Facility Inspections

Issued: February 08, 2017

Effective: February 08, 2017

Comment Circular C-12721 was issued 10/07/2016 soliciting comments for proposed revisions to MSRP Section G, WHEELS AND AXLES, Specification M-101 Axles, Carbon Steel Heat-Treated, concerning facility inspections and Specification M-107/M-208 Wheels, Carbon Steel, concerning microcleanliness and facility inspections.

Comments were received and proposed revisions were made to M-101 and M-107/M-208. This circular letter is for implementation of the revised M-101 and M-107/M-208.

The attachment to the Circular contains the following replacement pages:

G [M-101] 1-20

G [M-107/M-208] 1-42

These revisions to the Manual of Standards and Recommended Practices, Section G, WHEELS AND AXLES are now implemented effective immediately. Please update your library and be governed accordingly.

C-12822

Solicitation of comments – Revision to MSRP Section F, Standard S-6009 – Data Summary – Automatic Equipment Identification (AEI)

Issued: February 08, 2017

Effective:

This Circular Letter is intended to solicit comments for revisions proposed for Section F,Standard S-6009 – Data Summary – Automatic Equipment Identification (AEI).

The Equipment Health Monitoring Committee has proposed revisions to S-6009 regarding auto-close logic and auto-close display text. The proposed changes are in the attachment to this circular.

Comments from interested parties are being solicited under the provisions of AAR Standard S-050. Please submit any comments or questions to Michael Lesniak, Director – Asset Health, AAR at mlesniak@aar.org. All comments received within 30 days of issuance of this Circular will be considered by the EHMC prior to final action on the proposed revisions.

C-12823

Implementation: Revision to AAR MSRP Section E, BRAKES AND BRAKE EQUIPMENT, S-4001 Rubber Products, Clarification of Shelf Life

Issued: February 13, 2017

Effective: February 13, 2017

Paragraph 13.1 was inserted to clarify that the requirements for shelf life and storage are applicable only to rubber components that create an air seal. The remaining paragraphs have been renumbered accordingly.

The complete specification is attached to the circular letter. These changes are effective immediately. Questions regarding this circular letter can be directed to Devin Sammon, AAR Brake Systems Committee Manager via email at Devin_Sammon@aar.com.

C-12824

Informational Circular – Field Manual Appendix D – Information request Paints/Coatings

Issued: February 16, 2017

Effective:

This information request is in direct association with Circular Letter C-12745, the restructuring of Appendix D in the AAR Field Manual. The Appendix D Task Force is soliciting information from interested parties concerning paints/coatings to railcars. Paints and Coatings are defined as supplier specific name and type of paint and/or coatings applied to either the exterior or the interior (also referred to as interior linings) of a railcar. The Appendix D task force is looking to assemble a complete comprehensive list of all exterior paints and interior coatings to be used in establishing and maintaining all codification used in the railroad industry Car Repair Billing System, including Job Codes, that identify component specific information.

Please contact the Appendix D Task Force with any and all information concerning paints and coatings via email. The task force can be reached at fmappendixdtf@gmail.com.

C-12825

DRAFT Standard S-9101C.V1.0 – Locomotive Data and Recording System (LDARS) Event Data Acquisition Processor (EDAP), is available for review and comment, in support of AAR’s MSRP, Section K-II, Locomotive Electronics and Train Consist System Architect

Issued: February 20, 2017

Effective:

The Railway Electronics Standards Committee (RESC) has provided the Association of American Railroads (AAR) with a new Standard S-9101C.V1.0, Locomotive Data and Recording System (LDARS) Event Data Acquisition Processor (EDAP), which has been posted to the AAR’s SharePoint site.

Comments regarding this draft may be submitted to submitcomment@aar.org or using the Comment Form found on SharePoint. See circular for complete details.

C-12826

DRAFT Standard S-9101G.V1.0 – Locomotive Data and Recording System (LDARS) Common File Format Standard, is available for review and comment, in support of AAR’s MSRP, Section K-II, Locomotive Electronics and Train Consist System Architecture.

Issued: February 20, 2017

Effective:

The Railway Electronics Standards Committee (RESC) has provided the Association of American Railroads (AAR) with a new Standard S-9101G.V1.0, Locomotive Data and Recording System (LDARS) Common File Format Standard, which has been posted to the AAR’s SharePoint site.

The LDARS Common File Format applies to equipment installed after January 1, 2017.

This document presents the standard definition of the LDARS Common File Format.

This document will have a 30 day comment period. The time period will be effective as of February 20, 2017.

Comments regarding this draft may be submitted to submitcomment@aar.org or using the Comment Form found on SharePoint. See circular for complete details.

C-12827

Implementation of Revisions to Figure 154-B– Section 2 AAR Open Top Loading Rules Manual (OTLR)

Issued: February 21, 2017

Effective: February 21, 2017

The AAR’s Open Top Loading Rules Committee (OTLRC) has approved revisions to Figure 154-B– Section 2 of the AAR Open Top Loading Rules.

The changes to this figure replace 40 ft. as the nominal length in note 4 and in items H, J, L, and M.

The implementation of this revision to Section 2 is effective immediately and will be included in the next edition of the AAR’s OTLR Manual. In the interim, please insert the circular attachment for Figure 154-B in your copy Section 2 and be governed accordingly.

C-12828

Implementation of Revisions to Figure 134-A and the 200 Series Figures – Section 2 AAR Open Top Loading Rules Manual (OTLR)

Issued: February 21, 2017

Effective: February 21, 2017

The AAR’s Open Top Loading Rules Committee (OTLRC) has approved revisions to the Figures 134-A, 230, 240, 244, 247, 260, 263, 265, 267, 267-A, 280, and 285 – Section 2 of the AAR Open Top Loading Rules.

These changes include:

The requirement of Item W – Tie-down assemblies: consisting of a winch, ratchet and polyester woven strap 4 in. wide with 20,000 MBS. Locate near bearing pieces where practical. Place over bottom layer of pipe and anchor to opposite side of car, securing to prevent displacement. Winch taut using a minimum 30 in. bar. Maintain as much clearance from steel bands as possible to avoid damage to straps.

Note: This application may be used only on sketches utilizing Item E separators between the bottom and second layers.

Item W was added to the drawings.

Load weight charts were added to the notes to show the additional bands, bearing pieces and separators required when load weights are increased.

A note was added stating that, “Type 1A Grade 8 non-metallic strapping may be used if Item W tie-down assemblies are missing or defective. Strapping is to be attached to either lading strap anchors or stake pockets with appropriate hooks and/or buckles.”

The implementation of this revision to Section 2 is effective immediately and will be included in the next edition of the AAR’s OTLR Manual. In the interim, please insert the circular attachment for Figure 134-A and the 200 series figures in your copy Section 2 and be governed accordingly.

C-12829

Implementation of New Figure 851, Section 7 AAR Open Top Loading Rules Manual (OTLR)

Issued: February 21, 2017

Effective: February 21, 2017

The AAR Open Top Loading Rules Committee (OTLRC) has approved the implementation of new Figure 851, Section 7 of the AAR Open Top Loading Rules:

Containers, Folding, 20 FT To 40 FT Long, Four-High—Flatcars

The implementation of this revision to Section 7 is effective immediately and will be included in the next edition of the AAR’s OTLR Manual. In the interim, please insert the circular attachment for Figure 851 in your copy Section 7 and be governed accordingly.

C-12830

Solicitation of Comments on Proposed Change to Rule 7. Doorway Protection, Circular No. 42-K, General Rules Covering Loading or Carload Shipments of Commodities in Closed Cars (DP&FC)

Issued: February 21, 2017

Effective:

The AAR’s Damage Prevention & Freight Claim Committee (DP&FC) has approved changes to Rule 7. Doorway Protection, Circular N0. 42-K, General Rules Covering Loading or Carload Shipments of Commodities in Closed Cars.

Rule 7 currently reads:

When there is a possibility of lading falling or rolling out of doorway or coming in contact with sliding or plug type side doors, openings must be protected with wood doorway protection, steel straps or other material of sufficient strength and number and adequately secured. Cars equipped with plug type doors loaded with cylindrical items such as rolls of paper or drums require doorway protection unless specifically exempted by applicable commodity pamphlets.

Approved Rule Change:

When there is a possibility of lading falling or rolling out of doorway or coming in contact with sliding or plug type side doors, openings must be protected with wood doorway protection, steel straps or other material of sufficient strength and number and adequately secured. Cars equipped with plug type doors loaded with cylindrical items such as rolls of paper or drums require doorway protection unless specifically exempted by applicable commodity pamphlets.

Lumber wedged between car doorposts is not considered doorway protection.

Comments from interested parties are herewith solicited under the provisions of AAR Standard S-050. All comments received within 30 days of the issuance of this circular will be considered by the DP&FC. Please submit comments to Mr. Tom Feltault, Director Damage Prevention & Loading Services, TTCI, P.O. Box 11130, 55500 DOT Road, Pueblo CO 81001. Or email to Tom_Feltault@aar.com.

C-12831

Registration for NARMO 2017

Issued: February 21, 2017

Effective:

Dates: Wednesday, May 03, 2017 through Friday, May 05, 2017

Location: Grand Hyatt Denver

1750 Welton Street

Denver, Colorado

Full details can be found in the circular letter.

C-12832

Solicitation for Comments – Revision to MSRP Section H-II, ROLLER BEARING MANUAL, S-721 – Inspection Criteria, S-725 – Interchangeable Parts, and S-726 – Remanufacture Facility

Issued: February 23, 2017

Effective:

This Circular Letter is soliciting comments for revisions proposed for Section H-II, ROLLER BEARING MANUAL, Standard S-721 Mandatory Instructions and Practices, concerning images and inspection criteria, Standard S-725 Manufacture of Interchangeable Roller Bearing Components, concerning the table of interchangeable parts, and Standard S-726 Remanufacture of Roller Bearing Components, concerning the event that a facility ceases production for a length of time.

The Wheels, Axles, Bearings, and Lubrication Committee has proposed revisions to Standard S-721 Mandatory Instructions and Practices, Standard S-725 Manufacture of Interchangeable Roller Bearing Components, and Standard S-726 Remanufacture of Roller Bearing Components. The proposed changes are in the attachments to this circular.

The proposed revisions do not have costs associated with implementation.

Comments from interested parties are herewith solicited under the provisions of AAR Standard S-050. Please submit any comments or questions to Daniel Carter, Manager, WABL Committee at TTCI. Mr. Carter’s email address is daniel_carter@aar.com.

All comments received within 30 days of issuance of this Circular will be considered by the WABL Committee prior to final action on the proposed revisions.

C-12833

Class registrations are still open for the 2017 AAR M-1003 Quality Assurance training courses: Root Cause Analysis Class, Basic Auditor Training Class, and Advanced Auditor Training Class.

Issued: February 23, 2017

Effective:

The Association of American Railroads (AAR) Quality Assurance Committee has scheduled the following Quality Assurance Training classes:

M-1003 Root Cause & Corrective Action, March 21-22 in Denver, Colorado

M-1003 Basic Auditor Training, April 4-6 in Nashville, Tennessee

M-1003 Basic Auditor Training, May 16-18 in Toronto, Canada

M-1003 Advanced Auditor Training, April 25-27 in Lincoln, Nebraska

C-12834

Correction to Office Manual Price Matrices Effective January 1, 2017

Issued: February 23, 2017

Effective: January 1, 2017

Component Identification Indicator (CID) for slack adjuster Job Codes are in error and have been revised

The CID for Job Codes 1574, 1576, 1588, 1592, 1594, 1596, 1598, 1600, 1601 and 1603, was incorrectly set to N (CID not required). The Office Manual Price Matrices have been corrected to show the CID as required retroactive to January 1, 2017.

The corrected pertinent pages for all versions (US, Spanish and Canadian) are attached to the circular and should be inserted into the Price Matrices effective January 1, 2017.

A notification will be sent separately by Railinc regarding the updated Price Master data files.

C-12835

Solicitation of Comments on Proposed Archiving of MSRP Section L – LETTERING AND MARKING OF CARS, Recommended Practice RP-021, Equipment Identification and Warranty Administration

Issued: February 23, 2017

Effective:

The purpose of this Circular is to seek industry comments for the AAR Equipment Engineering Committee’s (EEC) plan to archive MSRP Section L LETTERING AND MARKING OF CARS, Recommended Practice RP-021 Equipment Identification and Warranty Administration.

It is the opinion of the EEC that the needed content of RP-021 was superseded by S-920, and that any remaining material is unnecessary for publication. Upon archiving of RP-021, the reference in Standard S-920 (third bulleted item above) will be deleted.

Comments from interested parties are herewith solicited under the provisions of AAR Standard S-050. All comments received within 30 days of the issuance of this circular will be considered by the EEC. Please submit comments to Jon Hannafious, Senior Manager, Equipment Engineering Committee at TTCI, at jon_hannafious@aar.com.

C-12836

Solicitation for Comment, Elimination of the Canadian Price Master

Issued: February 23, 2017

Effective: April 1, 2017

IMPORTANT NOTE: For companies that submit and/or receive bills using Canadian currency, it is critical that this information be distributed to all Car Repair Billing and IT personnel within your company that work with or are responsible for Car Repair Invoices submitted to and/or received from Railinc’s Data Exchange.

The AAR has been informed that the Railway Association of Canada (RAC) will no longer create the Canadian Price Master. The January 2017 Canadian Price Master was their last Price Master. Based on this information, the Canadian National and Canadian Pacific have decided not to pursue alternative methods to create a Canadian Price Master, opting instead to handle all Car Repair Bills, regardless of company location, using the US Price Master. This new process will be effective April 1, 2017.

The Car Repair Billing Procedures Manual will be updated to reflect this change.

Railinc is verifying that Canadian companies will be able to submit both US and Canadian bills in a single file or that two separate files will be accepted if one is US currency and one is Canadian currency.

Invoices with repair dates after March 31, 2017 and priced using the Price Master Currency Indicator “C”, will be rejected with error code “1”.

If you are interested in testing your file with Railinc, please contact csc@railinc.com.

In accordance with Rule 123, comments are herein solicited. Comments should be sent to the undersigned at nfimple@aar.org within 30 days of this letter for consideration. All comments received will be reviewed and considered by the Arbitration and Rules Committee and the Car Repair Billing Committee, with a targeted implementation date of April 1, 2017.

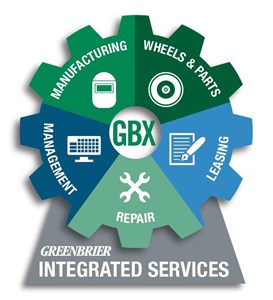

Greenbrier’s Regulatory Services Group

Peace of mind for your business.

The Regulatory Management Group, led by James Rader, provides regulatory, engineering, process consulting and advocacy support to the railcar repair industry and the petrochemical rail shipper community.

- ASNT Level III Subscription Services

- DOT Compliance Assessments (Corporate and Plant)

- DOT Hazardous Materials Training (Corporate and Plant)

- Expert Witness Services in Rail-Related Litigation

- Federal Government Claims Mitigation (e.g. FRA and PHMSA)

- Nondestructive Testing Programs

- Quality Assurance Program Development

- Regulatory Counsel and Policy Advocacy

- Railcar Repair Management (Design Review, Drawings, Engineering and AAR Approval Administration)

- Tank Car Reliability and Maintenance Programs (49 CFR Subpart F of Part 180)

- Tank Car Maintenance Data Collection and Reliability Performance Analysis

- Welding Program Development

For inquiries about these summaries or any of our services, please reach out to: regulatoryservices@gbrx.com

About Greenbrier Management Services (GMS)

Greenbrier Management Services (GMS) is North America’s most comprehensive railcar management solutions provider. GMS manages nearly 400,000 railcars and has invested over 20 years in developing technology, processes, and people to provide the best railcar management products and services in the industry. GMS is powered by proprietary software and the best subject matter experts in the railcar business.

COMPREHENSIVE. INTEGRATED. VALUE.

Combined, these two vitally important capabilities are able to deliver world-class solutions to every type of customer, from Class I railroads, lessors and industrial shippers to financial investors. GMS brings broad expertise to cover nearly any railcar management need that customers may have and its integrated solutions and reporting can be customized for any customer function or management need.