Shifting the business model to meet market needs, Greenbrier has proven its ability to build the right railcar at the right time.

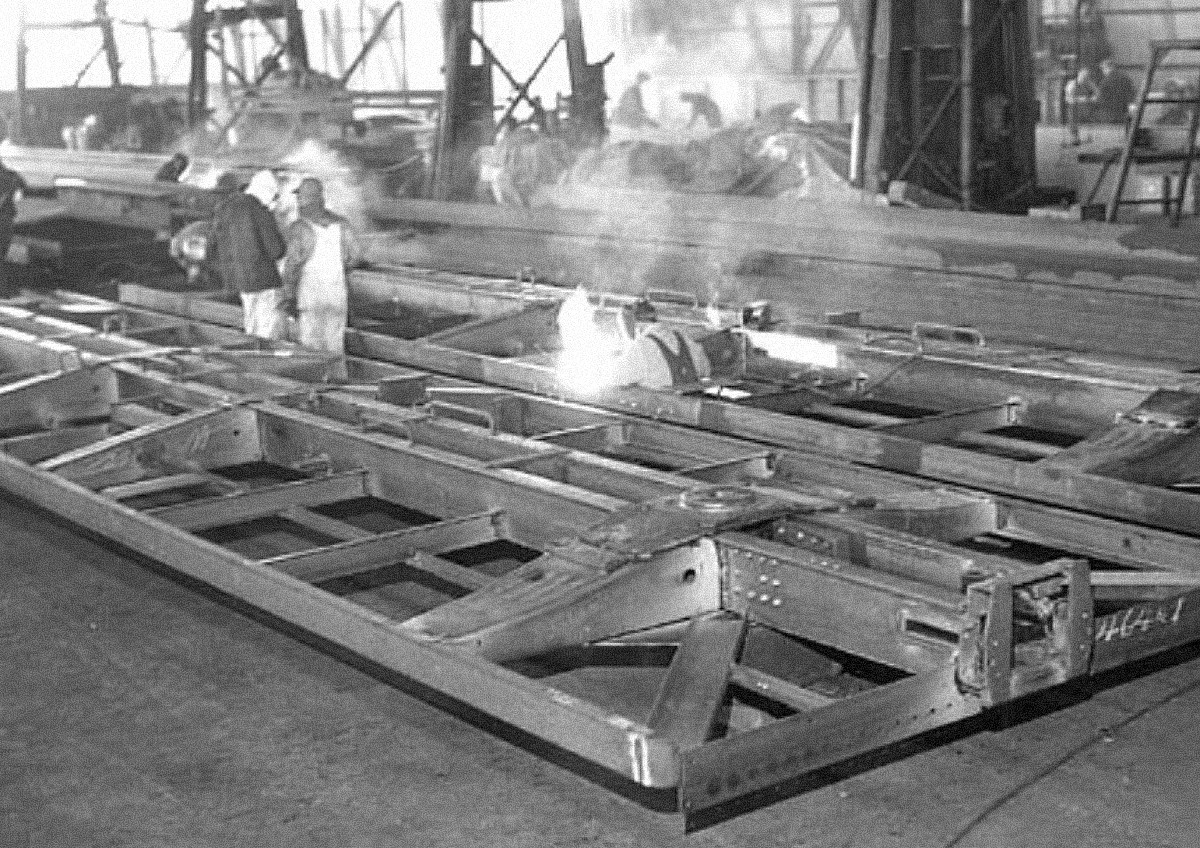

Railcars being assembled, from the Greenbrier Archives

Greenbrier’s reputation began on the water, well before the company became a name in the rail industry.

Gunderson built its foundation in marine construction, producing barges, tugs, tanks, large-diameter pipes, bridges, structural frames and dam gates. The work was profitable but unpredictable, honing the company’s strengths in precision fabrication, large-scale production and managing complex projects.

Those capabilities naturally opened the door to railcar manufacturing. Its defining innovation, the railcar, emerged directly from that early expertise. That foundation positioned the company to grow into a leader in modern railcar manufacturing.

The Greenbrier Archives

The Early Boxcar

Al Gunderson wanted a manufactured product with less hassle than marine products. By the late 1950s, business had slowed. The only job available was a bid to build 150 boxcar underframes for Southern Pacific Railway; a railroad Gunderson had worked with before. Their bid was accepted, setting the stage for a future in railcar production.

The boxcar underframes being assembled for Southern Pacific in 1958, from Gunderson, a History of an Oregon Company.

Southern Pacific was impressed with the boxcar underframes they received initially. Before the order was completed, they increased their order from 150 to 2,000 car frames. With experience building bridges, Gunderson already had some of the best welders in the business and car frames proved easier to build.

Al and Chet Gunderson were encouraged by their success making the underframes, the toughest part of the railcar. Gunderson’s facilities could be repurposed for manufacturing railcars. Keeping the company’s future in mind, they added the company to the nation’s list of freight car builders, looking for their first order.

The Gondola Railcar

In 1960, the Gundersons bid on 200 70-ton coal gondola cars for Union Pacific. This contract required a rethinking of the manufacturing process.

The gondola was considered one of the most difficult railcars to build at the time. To improve profitability, Gunderson began producing the drop-bottom doors in-house and purchased a 1,000-ton capacity press. This machine was repowered with a new hydraulic system and new steel columns for durability.

Each new order refined the process further. But greater efficiency created a new problem, space. Crews developed a solution called the Gunderson Railway, which connected Bay One and Bay Two and allowed workers to shuffle railcars throughout the shop.

Gunderson’s first railcar for Southern Pacific, delivered in 1960, from Gunderson, a History of an Oregon Company.

By the 1960s, the company focused on innovation. Moving from riveted to welded construction improved safety and profitability. More components were built in-house, which reduced costs and increased control.

In 1964, the Gunderson brothers sold the business to FMC’s Ordnance Division becoming a part of the Marine and Rail Equipment Division (MRED). At the time of the sale, the company produced 2,314 railcars, seven barges and two ship hulls.

The Woodchip Gondola Railcar

The next opportunity came with hauling wood chips. The industry standard relied on waterproof plywood sheathing that often-needed replacement. In 1966, Gunderson designed and built an all-steel gondola that was cheaper to build and maintain. It became a major hit with railroads and changed the industry overnight.

Success led to more innovation. Gunderson produced railcars that hauled copper ore, cattle, general merchandise, covered commodities, coal and lumber.

Demand for freight cars surged through the 1970s as modern boxcars replaced smaller and aging models. By 1978, national railcar production exceeded 90,000 units a year. In 1979, Gunderson built 6,027 railcars. But the boom was followed by a recession in the early 1980s, which pushed the industry toward containerization.

The 10-Pack

Intermodal shipping represented the future because of its versatility; containers could be moved by ships, trucks and trains. Atchison, Topeka & Santa Fe Railroad introduced the concept of the car. The Itel Corporation, a freight car leasing company, brought the patent to MRED, Gunderson’s division, to build it.

The design became known as the 10-Pack. It weighed far less than 10 individual cars and required fewer couplers. Lower weight meant lower fuel costs and a more sustainable operating model. MRED built 704 of these platforms for Itel between 1981 and 1984.

The Twin-Stack

The next major advancement was the double-stack car, developed by Southern Pacific and Sea-Land. By lowering the floor of the railcar, railroads could stack two containers where only one fit before, allowing twice the freight in the same footprint. The idea emerged in the 1970s but didn’t gain traction until the industry was ready to adopt it more broadly.

The Twin Stack, 1984, from the Greenbrier Archives

Greenbrier leaders saw an opportunity where others had stalled. President Bill Furman, MRED Vice President Bill Galbraith and Co-founder Alan James knew the double-stack design had a future. After purchasing Greenbrier Leasing Corporation in 1981, they focused on refining and marketing a lighter, more durable version called the Twin-Stack. Their approach worked. The leasing fleet grew from 300 cars in 1981 to nearly 3,000 in 1984 and between 1985 and 1988, Gunderson built 4,160 Twin-Stack cars. Today, double-stack service is standard for many rail shippers.

The Center Partition Railcar

The next step in intermodal evolution was the center partition car. It was a flatcar with a vertical divider down the middle and bulkheads at each end, which strengthened the frame and supported lumber loads. The design significantly reduced damage in transit.

Center Partition Car from Gunderson, a History of an Oregon Company

Gunderson improved the design and introduced it to the Northwest market in 1986. Orders quickly increased from 345 cars in 1986 to 2,000 a year by 1987.

The Return of the Boxcar

In a full-circle moment, Gunderson returned to the boxcar business in the late 1980s. It received a $6 million order for 100-ton boxcars from Montana Rail Link. Burlington Northern ordered 250 more, followed by an order for 50 cars for Greenbrier’s lease fleet. As the nation’s sole boxcar producer for several years, Gunderson held more than 80 percent of the U.S. market for a decade.

Built For What’s Next

Gunderson proved resilient, consistently meeting market demands throughout its history. Today, the company remains a cornerstone of modern railcar manufacturing. Greenbrier has been built on that early success—on the team members who pushed boundaries, the innovations that reshaped the market and the flexibility to deliver quality products when the industry needed them most. The evolution of the railcar continues and Greenbrier is still setting the pace.