About AAR Circular Letters

Circular letter summaries are produced monthly by Greenbrier’s Regulatory Management team, a division of Greenbrier Management Services Group.

AAR circular letters provide information of general applicability to the railroad industry, including proposed and final rules, revisions, standards and recommended practices, and calls for comments. These summaries provide the main points of circular letters issued in the prior month, as well as important implementation deadlines.

For access to the complete circular letter, please go to my.aar.org/circulars. Circular letters are a fee-based service provided by the AAR’s Transportation Technology Center Incorporated (TTCI). You may subscribe online at publications@aar.com or call 719.584.0538.

Implementation Circulars

C-13752

Implementation Circular: Revisions to Office Manual Rule 88.C.1.d(2) and Rule 88.C.3.c(17)

Issued: March 3, 2021

Effective: April 1, 2021

The changes proposed in C-13717, as well as the following, have been approved and will be implemented with the release of the April 2021 AAR Office Manual revisions:

Rule 88.C.1.d(2)(g):

Replacing the entre car body (which may or may not include replacing the underframe). The built date and EIN of the modified car in Umler will be the same as the original car. The car mark and number that was stamped onto the original sill must be stamped onto the new car body sill. The facility conducting the modification must have approval under AAR Standard S‐2034. Updating of the safety appliances per item (17) of the minimum mechanical requirements chart is applicable. The entire original car body must be scrapped.

Tank cars which are designated to carry lading of anhydrous ammonia, or of poisonous by inhalation/toxic by inhalation as defined in 49 CFR § 171.8, must have wheel sets with new wheels and new or reconditioned 6 ½” x 9” journal roller bearings. Testing of axles ultrasonically in accordance with MSRP M‐101 (for new) or MSRP S‐659 (for reconditioned) is applicable.

C-13753

IMPLEMENTED. AAR Manual of Standards and Recommended Practices (MSRP), Section K-1 Railway Electronics Systems Architecture and Concept of Operations, Standard S-9081.V1.2

Issued: March 8, 2021

Effective: March 8, 2021

Standard S-9081.V1.2, attached to the circular, contains the format and establishes some of the data contents of the Train Sheet Transaction Set (EDI 161), Applicable Advise – Train Sheet (EDI 824) and Train Consist Transaction Set (EDI 418J) for use within the context of Electronic Data Interchange (EDI) environment. These transaction sets can be used to allow railroads to exchange train information and ensure that the crews operating equipment on the railroads are aware of current operating conditions.

C-13754

Additions to MSRP Section F, SENSORS | S-920 AAR Component Identification Bar Code Standard: Tank Car Service Equipment: Pressure Relief Valves (PRV)

Issued: March 10, 2021

Effective: July 1, 2021

The revised standard, attached to the circular, is implemented and effective July 1, 2021. For specific information on tank car pressure relief valve bar codes refer to paragraph 21.0 and Appendix I. This release is in concert with CPC-1375 and reflects corresponding technical standards changes to MSRP C-III, Chapter 1 and Appendices A and D. Modifications will be incorporated in the appropriate sections of the next issue of the Manual of Standard and Recommended Practices.

Manufacturers and companies that recondition pressure relief valves (PRV) are hereby required to add approved AAR bar code labels to their product beginning on July 1, 2021.

Be advised that due to internal, administrative changes; MSRP Section F, Paragraph 3.2.1 through 3.2.5 are temporarily superseded by instructions provided in CPC-1375. The process described in CPC-1375 applies only bar codes approved for use, until a permanent update is approved and released.

CPC-1375

Implementation of Revisions to MSRP Section C-III, Specification for Tank Cars (M-1002), Chapter 1, Appendix A, and Appendix D (Docket T100.22.1)

Issued: March 10, 2021

Effective: July 1, 2021

The Component Tracking program is a multi-phase, multi-year initiative to create an industry process for capturing railcar equipment component data to provide improved visibility into the health status and history of equipment and components for identification/traceability, trend analysis, and recall efficiency.

The AAR Tank Car Committee is moving forward with component tracking of tank car service equipment, starting with pressure relief valves, which affects several MSRPs, as well as the Field and Office Manual.

The following is a summary of the final revisions:

Chapter 1 (attached to the circular)

New definitions added to support component tracking of tank car service equipment.

Clarification made to Table 1.19 to reflect revisions made to Appendix D

Identifies who is responsible for identification, registration, and association of component tracking of tank car service equipment.

Appendix A (attached to the circular)

Standardizes the marking/identification requirements for tank car service equipment to align with component tracking registration.

Establishes the effective date of July 1, 2021 for component tracking of pressure relief valves.

Appendix D (attached to the circular)

Specifies when and how to associate tank car service equipment to the tank car.

Removes the certificate of test form requirements for pressure relief valves since this information is now contained within the component ID.

AAR MSRP Section F, Standard S-920

AAR circular C-13754, issued in concert with this CPC, implements final action from circular C-13719 by adding pressure relief valves as a new section and appendix to S-920.

AAR Field and Office Manual

C-13727 was published 12/31/2020 which included the implementation details within Rule 81. Please Note: The effective date is July 1, 2021 and Rule 81.B.5 will be updated in the July supplement of the AAR Field Manual.

CPC-1376

Implementation of Revisions to MSRP Section C-III, Specification for Tank Cars (M-1002), Chapter 1 and Appendix T (Docket T88.1-93)

Issued: March 19, 2021

Effective: March 19, 2021

Revisions to C-III, Chapter 1, and Appendix T, have been approved.

The following is a summary of the final revisions:

Chapter 1 (attached to CPC-1375)

Revised definitions of “Nondestructive testing (NDT)” and “NDT Level III” to align with M-1002 Appendix T.

Appendix T (attached to the circular)

Specifies NDT Level III must be certified by the American Society for Nondestructive Testing (ASNT) or the Canadian General Standards Board (CGSB).

Adds Hydrostatic Leak Testing (HLT) as an NDT technique. Each facility that performs hydrostatic leak testing must incorporate HLT into their NDT program no later than January 1, 2022.

Adds Electromagnetic Testing (ET) as an NDT method.

Revised the Automated Ultrasonic Testing NDT technique.

Revised Visual Inspection (VT) NDT method. Visual weld inspection (VWI) that existed in the previous Appendix T will now become limited certification under VT for welds only.

C-13762

Implementation Circular: Revisions to Office Manual Rule 88, Form 88-C, Rule 93 and Appendix E

Issued: March 30, 2021

Effective: April 1, 2021

Revisions to Office Manual Rule 88, Rule 93, and Appendix E have been approved and will be implemented effective April 1, 2021 with the release of the April 2021 AAR Office Manual revisions.

CPC-1378

Clarification on Serial Number Markings on Tank Car Service Equipment

Issued: March 30, 2021

Effective: March 30, 2021

This CPC is a clarification in reference to CPC-1375 concerning changes to Appendix A marking/identification requirements for tank car service equipment to align with component tracking registration (issued on March 10, 2021).

For service equipment built prior to July 1, 2021, the serial number must be permanently marked by the manufacturer based on the built after effective date as previously specified in Appendix A (prior to CPC-1375).

For service equipment manufactured/assembled after July 1, 2021, the serial number must be permanently marked by the C4a or C4m facility as specified in the Appendix A issued under CPC-1375.

In both cases, all original markings must be maintained for the life of the service equipment. For convenient reference, the built after effective dates for each service equipment type are summarized in a table included in the circular.

C-13763

IMPLEMENTED. AAR Manual of Standards and Recommended Practices (MSRP), Section K-VI Railway Data Management and Communications, S-9558.V1.0

Issued: March 31, 2021

Effective: March 31, 2021

Standard S-9558.V1.0 describes the common IP address blocks reserved among the railroads participating in Positive Train Control (PTC). The purpose of this document is to ensure that railroads are not using the same IP addressing elsewhere in the network for other communications purposes. S-9558.V1.0 (attached to the circular) will be incorporated into the next issue of the MSRP, Section K-VI Railway Data Management and Communications. In the interim, insert the attachment into your copy of the MSRP Section K-VI and be governed accordingly.

Call for Comment

C-13751

Solicitation of Comments for Revisions to Circular 42, General Rules Covering Loading or Carload Shipments of Commodities in Closed Cars (DP&FC)

Issued: March 2, 2021

Effective: 30 days for comment.

Wording updates for appropriate document and table references were completed in Section 3 – Distribution of Weight Lengthwise in Cars, Section 5 – Loading, Blocking, and Bracing – Box Cars, and Section 6 – Doorway Protection. The proposed document is attached to the circular.

C-13761

Solicitation of Comments for Revisions to MSRP Section S-III, COUPLER AND YOKE DETAILS, Standard S-105, Coupler E Type Detail Parts, regarding making reduced slack components standard for new production

Issued: March 30, 2021

Effective: 30 days for comment.

Proposed changes include the following: Older knuckle types (E50AE, E50ARE, and E50BE) and an older lock type (E42AE) were removed. E40AE top operated locks are not reduced slack but were retained as there are no reduced slack top operated locks. References to M-211 Grade E steel for knuckles were updated to M-201 Grade E steel. Changes are indicated with change bars in the attached file. The proposed revision is attached the circular.

C-13764

DRAFT S-9371.V4.0 – PTC Onboard Segment – Energy Management Interface Control Document (ICD) is available for review and comment. In support of AAR’s MSRP, Section K-IV, Office Architecture and Railroad Electronics Messaging

Issued: March 31, 2021

Effective: 15 days for comment.

The proposed document concerns the messages passed between a PTC onboard segment and an Energy Management (EM) system that operates on a locomotive. The PTC onboard segment connects to the Energy Management (EM) as an EMP client, and Energy Management acts as an EMP server. The DRAFT document and Comment Form can be found at: https://DRAFT S-9371.V4.0.

Notice of Circulars

C-13756

Informational Circular, Canadian Car Repair Facility Labor Rate – Effective April 1, 2021

Issued: March 12, 2021

Effective: April 1, 2021

The Canadian Car Repair Facility Labor Rate, effective April 1, 2021 in the Canadian Price Master is $205.74 CAD.

C-13755

Informational Circular, Car Repair Facility Labor Rate – Effective April 1, 2021

Issued: March 12, 2021

Effective: April 1, 2021

The Car Repair Facility Labor Rate, effective April 1, in the 2021 AAR Office Manual is $130.64.

C-13760

Notice of Implementation of Revisions to Figures 87, 87-B, 88-B, 88-F, 88-K, and 101-A – Section 6 of the AAR Open Top Loading Rules Manual (OTLR)

Issued: March 23, 2021

Effective: March 23, 2021

The revisions to figures in Section 6 OTLR for correct chain charts includes the following: Changing verbiage that references “Working Load Limit (WLL)” or “Proof Test” to “Minimum Breaking Strength (MBS)” and related values. The implementation of these revisions is effective immediately and will be included in the next edition of the OTLR manual. In the interim, insert the circular attachments for Figures 87, 87-B, 88-B, 88-F, 88-K, and 101-A into your Section 6 copy and be governed accordingly.

Carriers are asked to ensure that copies of this circular letter are distributed to all concerned shippers and railroad personnel for their attention and guidance.

C-13759

Notice of Implementation of Revisions to Figures 58-B, 58-C, 58-E, 63-A, and 83 – Section 6 of the AAR Open Top Loading Rules Manual (OTLR)

Issued: March 23, 2021

Effective: March 23, 2021

The revisions to figures in Section 6 OTLR for correct chain charts includes The following: Changing verbiage that references “Working Load Limit (WLL)” or “Proof Test” to “Minimum Breaking Strength (MBS)” and related values. A new Figure 58-E “VEHICLES, AMPHIBIOUS COMBAT VEHICLE 67,650 LB OR LESS – FLATCARS, CHAIN TIEDOWN” has also been added. The implementation of these revisions is effective immediately and will be included in the next edition of the OTLR manual. In the interim, insert the circular attachments for Figures 58-B, 58-C, 58-E, 63-A, and 83 into your Section 6 copy and be governed accordingly.

Carriers are asked to ensure that copies of this circular letter are distributed to all concerned shippers and railroad personnel for their attention and guidance.

C-13758

Notice of Implementation to archive Figure 58: VEHICLES, LIGHT ARMORED AND SIMILAR, 30,000 LB AND UNDER—FLATCARS – Section 6 of the AAR Open Top Loading Rules Manual (OTLR)

Issued: March 23, 2021

Effective: March 23, 2021

The archival changes to Sections 4 and 6 OTLR are effective immediately and will be included in the next edition of the AAR’s OTLR Manual. In the interim, insert the circular attachment for Figure 58 into your Section 6 copy and be governed accordingly.

Carriers are asked to ensure that copies of this circular letter are distributed to all concerned shippers and railroad personnel for their attention and guidance.

C-13757

Notice of Implementation of Revisions to Figures 1-B, 21-D, 36-B, 48-C, 48-D, and 54-B – Section 6 of the AAR Open Top Loading Rules Manual (OTLR)

Issued: March 23, 2021

Effective: March 23, 2021

The revisions to figures in Section 6 OTLR for correct chain charts includes the following: Changing verbiage that references “Working Load Limit (WLL)” or “Proof Test” to “Minimum Breaking Strength (MBS)” and related values. The implementation of these revisions is effective immediately and will be included in the next edition of the OTLR manual. In the interim, insert the circular attachments for Figures 1-B, 21-D, 36-B, 48-C, 48-D, and 54-B into your Section 6 copy and be governed accordingly.

Carriers are asked to ensure that copies of this circular letter are distributed to all concerned shippers and railroad personnel for their attention and guidance.

Greenbrier’s response to COVID-19

As this challenging time continues, Greenbrier would like to provide an update on operations and our continued dedication to our customers, employees, and communities. As rail workers and contractors are designated “Essential Critical Infrastructure Workers”, Greenbrier’s manufacturing and repair facilities are fully operational. Our office teams are available as well, though most are working remotely. We encourage you to contact your Greenbrier representative if you have any questions or concerns—we are here for you.

For more information, visit our webpage that details Greenbrier’s response to COVID-19.

Greenbrier’s Regulatory Services Group

Peace of mind for your business.

The Regulatory Management Group, led by James Rader, provides regulatory, engineering, process consulting and advocacy support to the railcar repair industry and the petrochemical rail shipper community.

- ASNT Level III Subscription Services

- DOT Compliance Assessments (Corporate and Plant)

- DOT Hazardous Materials Training (Corporate and Plant)

- Expert Witness Services in Rail-Related Litigation

- Federal Government Claims Mitigation (e.g. FRA and PHMSA)

- Nondestructive Testing Programs

- Quality Assurance Program Development

- Regulatory Counsel and Policy Advocacy

- Railcar Repair Management (Design Review, Drawings, Engineering and AAR Approval Administration)

- Tank Car Reliability and Maintenance Programs (49 CFR Subpart F of Part 180)

- Tank Car Maintenance Data Collection and Reliability Performance Analysis

- Welding Program Development

For inquiries about these summaries or any of our services, please reach out to: regulatoryservices@gbrx.com

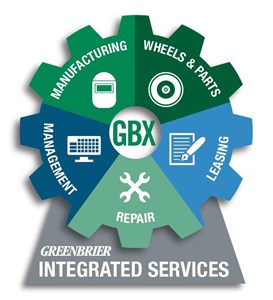

About Greenbrier Management Services (GMS)

Greenbrier Management Services (GMS) is North America’s most comprehensive railcar management solutions provider. GMS manages nearly 400,000 railcars and has invested over 20 years in developing technology, processes, and people to provide the best railcar management products and services in the industry. GMS is powered by proprietary software and the best subject matter experts in the railcar business.

COMPREHENSIVE. INTEGRATED. VALUE.

Combined, these two vitally important capabilities are able to deliver world-class solutions to every type of customer, from Class I railroads, lessors and industrial shippers to financial investors. GMS brings broad expertise to cover nearly any railcar management need that customers may have and its integrated solutions and reporting can be customized for any customer function or management need.