About AAR Circular Letters

Circular letter summaries are produced monthly by Greenbrier’s Regulatory Management team, a division of Greenbrier Management Services Group.

AAR circular letters provide information of general applicability to the railroad industry, including proposed and final rules, revisions, standards and recommended practices, and calls for comments. These summaries provide the main points of circular letters issued in the prior month, as well as important implementation deadlines.

For access to the complete circular letter, please go to my.aar.org/circulars. Circular letters are a fee-based service provided by the AAR’s Transportation Technology Center Incorporated (TTCI). You may subscribe online at publications@aar.com or call 719.584.0538.

Implementation Circulars

C-13300

Implementation of Revisions to Figure 14-A – Section 2 of the AAR Open Top Loading Rules Manual (OTLR)

Issued: April 6, 2019

Effective: April 6, 2019

The implementation of these revisions to Section 2 is effective immediately and will be included in the next edition of the AAR’s OTLR manual. In the interim, please insert the circular attachment for Fig. 14-A in your copy of Section 2 and be governed accordingly. Carriers are asked to ensure that copies of this circular letter are distributed to all concerned shippers and railroad personnel for their attention and guidance.

C-13301

Implementation of New Figure 128-B and Archive Figures 128 and 128-A – Section 2 of the AAR Open Top Loading Rules Manual (OTLR)

Issued: April 6, 2019

Effective: April 6, 2019

The implementation of these revisions to Section 2 is effective immediately and will be included in the next edition of the AAR’s OTLR manual. In the interim, please insert the circular attachment for Figure 128-B in your copy of Section 2 and be governed accordingly. Carriers are asked to ensure that copies of this circular letter are distributed to all concerned shippers and railroad personnel for their attention and guidance.

C-13302

Implementation of Revision to MSRP Section N, Specification M-992, Designated Satellite Shop Repair for Multi-Level Auto Rack Cars

Issued: April 6, 2019

Effective: April 6, 2019

Specification M‐992 has been revised and Section 2.6 (rack condition scoring) has been removed. The revisions are attached to the circular. Changes to MSRP Section N, Specification M‐992 are now implemented and effective immediately and will be incorporated in the next issue of MSRP Section N. In the interim, please insert the circular attachment into your copy of MSRP Section N and be governed accordingly.

C-13303

Implementation of Revisions to MSRP Section N, Specification M-970, Condition Based Certification of Multi-Level Auto Rack Cars

Issued: April 6, 2019

Effective: April 6, 2019

An editorial revision has been made to Specification M‐970, the new language is included in the circular attachment. Changes to MSRP Section N, Specification M‐970 are now implemented and effective immediately and will be incorporated in the next issue of MSRP Section N. In the interim, please insert the circular attachment into your copy of MSRP Section N and be governed accordingly.

C-13307

Implementation of Revisions to General Rule 21 and Glossary – Section 1 of the AAR Open Top Loading Rules Manual (OTLR)

Issued: April 18, 2019

Effective: April 18, 2019

The implementation of these revisions is effective immediately and will be included in the next edition of the OTLR’s manual. In the interim, please insert the circular attachments for General Rule 21 and Glossary in your Section 1 copy and be governed accordingly. Carriers are asked to ensure that copies of this circular letter are distributed to all concerned shippers and railroad personnel for their attention and guidance.

C-13308

Implementation of Revision to Figure 78-B – Section 6 of the AAR Open Top Loading Rules Manual (OTLR)

Issued: April 18, 2019

Effective: April 18, 2019

The implementation of this revision is effective immediately and will be included in the next edition of the OTLR’s manual. In the interim, please insert the circular attachment for Figure 78-B in your Section 6 copy and be governed accordingly. Carriers are asked to ensure that copies of this circular letter are distributed to all concerned shippers and railroad personnel for their attention and guidance.

C-13309

Implementation of Revisions to AAR Intermodal Interchange Rules, Section A, Rule 21, Appx A, Appx B, Appx F, Job Code Photo Glossary, IBC Photo Glossary, and Specialized Container Photo Glossary, Chassis Shipping Units, and Billing Procedures

Issued: April 19, 2019

Effective: April 19, 2019

Revisions (attached to the circular) are now implemented and effective immediately. Please update your library and be governed accordingly.

C-13310

Implementation of Revisions to MSRP Section I, Intermodal Equipment Manual, M-930, M-931, M-998, RP-853, Appendix E CSU Testing, Lift Pad, and IBC Tension Testing

Issued: April 19, 2019

Effective: April 19, 2019

M-930, M-931, M-998, and RP-853 (attached to the circular) are now implemented and effective immediately. This modification will be incorporated in the next issue of the Manual of Standards and Recommended Practices, Section I. Please update your library and be governed accordingly.

C-13311

Implementation of Revisions to MSRP Section G-II, WHEEL AND AXLE MANUAL, S-659, RP-631, RP-632, and RP-633, Southern CJ-33, Wheel Storage, Bearing Storage, and Vertical Split Rim

Issued: April 19, 2019

Effective: April 19, 2019

S-659, RP-631, RP-632, and RP-633 (attached to the circular) are now implemented and effective immediately. This modification will be incorporated in the next issue of the Manual of Standards and Recommended Practices, Section G-II. Please update your library and be governed accordingly.

C-13312

Implementation of Revision to MSRP Section C, CAR CONSTRUCTION FUNDAMENTALS AND DETAILS: Adoption of Recommended Practice RP-2018, Handholds, Steps, and Ladders for Interior Access

Issued: April 23, 2019

Effective: April 23, 2019

RP-2018 provides guidance for appliances that are not mandatory per AAR Standard S-2044 (Safety Appliance Requirements for Freight Cars) but may be installed to provide access to the interior of cars. Compliance with RP-2018 is recommended but not mandatory. RP-2018, attached to the circular, is now implemented and effective immediately. This revision will be incorporated in the next issue of the Manual of Standards and Recommended Practices, Section C. Please update your library and be governed accordingly.

Call for Comment

C-13314

Subject: Solicitation for Comment, Revisions to Office Manual, Rule 112.E.1 and CRB Procedures Manual

Issued: April 29, 2019

Effective: 30 days for comment

Important Note: It is recommended that this information be shared with all Car Repair Billing and IT personnel in your company that work with or are responsible for Car Repair Invoices submitted to and/or received from Railinc’s Data Exchange.

At the April 2019 meeting of the Arbitration and Rules Committee, a proposal as advanced by the Car Repair Billing Committee to revise Office Manual Rule 112.E.1 and the Car Repair Billing Procedures Manual was reviewed and approved. Access the AAR circular letter to view the proposed revisions in its entirety.

C-13315

Subject: Solicitation of Comments, Revisions to Field Manual, Rules 36 & 37

Issued: April 29, 2019

Effective: 30 days for comment

At the April 2019 meeting of the Arbitration and Rules Committee a proposal by the WABL Committee to revise Field Manual Rules 36 & 37, was reviewed and approved.

Proposed Rule 36.E.7:

E.7 – When replacing wheel sets for cause, cars designated in Umler as IGRL Code 1 may only have bearing sizes of 6-1/2 x 9 or 7 x 12 applied. Roller bearing adapters replaced to correspond with the correct bearing size and not having another defect shall be billed as Why Made Code 08.

Proposed Rule 37.E.2:

- When exchanging adapters per Rule 36, Why Made Code 11 should be used if adapter is not defective. Except when cars are designated in Umler as IGRL Code 1 adapters replaced to correspond with the correct bearing size and not having another defect shall be billed as Why Made Code 08.

C-13316

Subject: Solicitation of Comments, Revisions to Field Manual, Rules 19, 20 and Appendix A.

Issued: April 30, 2019

Effective: 30 days for comment

At the April 2019 meeting of the Arbitration and Rules Committee (ARB) a proposal by CSTCC to revise Field Manual Rules 19 and 20 was reviewed and approved. Additionally ARB reviewed and approved the addition of “Cause for Attention” to Appendix A. Access the AAR circular to see description and details of the revised rules in their entirety.

C-13317

Subject: Solicitation of Comments, Revisions to Field Manual, Rule 22

Issued: April 30, 2019

Effective: 30 days for comment

At the April 2019 meeting of the Arbitration and Rules Committee a proposal by CSTCC to revise Field Manual Rule 22.A, was reviewed and approved. Access the AAR circular to view the entire text of the revision.

C-13318

Subject: Solicitation of Comments, Revisions to Field Manual, Rule 59

Issued: April 30, 2019

Effective: 30 days for comment

At the April 2019 meeting of the Arbitration and Rules Committee a proposal by CSTCC to revise Field Manual Rule 59, was reviewed and approved. Access the AAR circular to view the entire text of the revision.

Notice Circulars

C-13225

AAR Change in Location Requirements for AAR M-1003 Quality Assurance Certified Facilities

Issued: April 1, 2019

Effective: April 1, 2019

This Circular Letter clarifies AAR’s policy for changes in location of M-1003 Quality Assurance certified facilities. If a facility changes its physical location only (i.e., no change in activity code(s), personnel, processes, procedures, or equipment), the facility must email the AAR Manager of the AAR Quality Assurance Committee 60 days in advance a dated letter on company letterhead. The facility must include in the letter all of the following information: the facility name, QA-Code, the current address, and the new address, and the date of facility relocation. The facility must affirmatively represent in the letter that there is no change activity code(s), personnel, processes, procedures, or equipment. If a facility changes its physical location and will make changes to its activity code(s), personnel, processes, procedures, or equipment, the facility must apply for new M-1003 certification for at the new location. In such a case, the existing certification will not be valid for operations at the new location. If only the physical location has changed, AAR will process the request, assign a new QA-Code and notify the facility that the next facility audit will comprise of an M-1003 recertification audit. This policy is effective immediately.

CPC-1347

Replacement for CPC-1339 – AAR Change in Location Requirements for AAR M-1002 Tank Car Certified Facilities

Issued: April 1, 2019

Effective: April 1, 2019

This Circular Letter clarifies AAR’s policy for changes in locations of M-1002 certified tank car facilities. If a facility changes its physical location only (i.e., no change in certification elements (including activity code(s), material groups and repair level capabilities, where applicable), personnel, processes, procedures, or equipment), the facility must email the AAR director of tank car safety 60 days in advance a dated letter on company letterhead. The facility must include in the letter all of the following information: the facility name, station stencil (also known as quality assurance “QA” Code), the current address, and the new address, and the date of facility relocation. The facility must affirmatively represent in the letter that there is no change in its certification elements (including activity code(s), material groups and repair level capabilities, where applicable), personnel, processes, procedures, or equipment. If a facility changes its physical location and will make changes to its certification elements (including activity code(s), material groups and repair level capabilities, where applicable), personnel, processes, procedures, or equipment, the facility must apply for new certification to M-1002 and M-1003 at the new location. In such a case, the existing certification will not be valid for operations at the new location. If only the physical location has changed, AAR will process the request, assign a new station stencil (aka QA Code) and notify the facility that the next AAR facility audit will consist of an M-1002 and M-1003 recertification audit. This policy is effective immediately.

C-13305

3 Month Extension to Mandatory Compliance Date for S-4027 Single Car Test Revision Criteria

Issued: April 12, 2019

Effective: April 12, 2019

Standard S‐4027‐2018 became effective July 1, 2018sara

S‐4027‐2018 compliance will be mandatory August 1, 2019

Standard S‐4027‐2015 will be sunset August 1, 2019

C-13306

Informational Circular, Handling Requirements for Submerged Air Brake Equipment and Roller Bearings

Issued: April 12, 2019

Effective: April 12, 2019

The purpose of this circular letter is to remind the industry of rules in place for the proper handling of air brake, slack adjuster, and roller bearing components submerged for any reason. “Submerged,” as defined in Appendix A of the AAR Field Manual, is when any portion of a component has been under water. The rules that pertain to “submersion” are described and reviewed in the circular letter.

As a reminder, Instruction Leaflet No. 2391, Sup. 1, Repair Track Maintenance—Freight Brake Equipment “AB” Type, is a required document per Rule 1.5.b.3 of the AAR Field Manual. It can also be found at http://www.aar.com/standards/mid-field_manual.htm.

CPC-1348

Subject: Recommended Railroad Operating Practices for Transportation of Hazardous Materials

Issued: April 26, 2019

Effective: May 1, 2019

AAR’s Safety and Operations department is amending AAR Circular No. OT-55-Q by deleting the Canadian Only “T” code section from Appendix A and B. This amendment reflects the changes in the Canadian Transportation of Dangerous Goods Regulations (TDGR) and only impacts Appendices A & B of Cirucular No. OT-55-Q.

C-13313

Subject: Informational Circular, Revisions to Office Manual, Rule 112.H.3

Issued: April 29, 2019

Effective: April 29, 2019

At the April 2019 meeting of the Arbitration and Rules Committee, a proposal by the Car Repair Billing Committee to revise Office Manual Rule 112.H.3 was reviewed and approved. The revised rule will be included in the July 2019 release of the Office Manual.

Proposed & Approved Office Manual Rule 112.H.3 revisions:

“Questionable Charges” do not include invalid exceptions listed in Appendix Y.1.1 of the Car Repair Billing Procedures Manual.

Upcoming Events

Petrochemical Downstream Exhibition & Conference 2019

June 11-12, 2019

Houston, TX

The Greenbrier Companies is excited to be exhibiting at this event hosted by Downstream. Stop by our booth at H59, we look forward to seeing you!

Registration and program details can be found at: https://www.petchem-update.com/downstream/

Greenbrier’s Regulatory Services Group

Peace of mind for your business.

The Regulatory Management Group, led by James Rader, provides regulatory, engineering, process consulting and advocacy support to the railcar repair industry and the petrochemical rail shipper community.

- ASNT Level III Subscription Services

- DOT Compliance Assessments (Corporate and Plant)

- DOT Hazardous Materials Training (Corporate and Plant)

- Expert Witness Services in Rail-Related Litigation

- Federal Government Claims Mitigation (e.g. FRA and PHMSA)

- Nondestructive Testing Programs

- Quality Assurance Program Development

- Regulatory Counsel and Policy Advocacy

- Railcar Repair Management (Design Review, Drawings, Engineering and AAR Approval Administration)

- Tank Car Reliability and Maintenance Programs (49 CFR Subpart F of Part 180)

- Tank Car Maintenance Data Collection and Reliability Performance Analysis

- Welding Program Development

For inquiries about these summaries or any of our services, please reach out to: regulatoryservices@gbrx.com

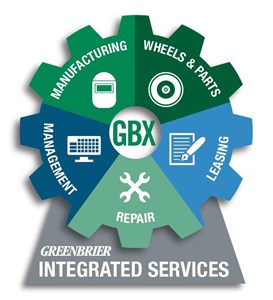

About Greenbrier Management Services (GMS)

Greenbrier Management Services (GMS) is North America’s most comprehensive railcar management solutions provider. GMS manages nearly 400,000 railcars and has invested over 20 years in developing technology, processes, and people to provide the best railcar management products and services in the industry. GMS is powered by proprietary software and the best subject matter experts in the railcar business.

COMPREHENSIVE. INTEGRATED. VALUE.

Combined, these two vitally important capabilities are able to deliver world-class solutions to every type of customer, from Class I railroads, lessors and industrial shippers to financial investors. GMS brings broad expertise to cover nearly any railcar management need that customers may have and its integrated solutions and reporting can be customized for any customer function or management need.