About AAR Circular Letters

Circular letter summaries are produced monthly by Greenbrier’s Regulatory Management team, a division of Greenbrier Management Services Group.

AAR circular letters provide information of general applicability to the railroad industry, including proposed and final rules, revisions, standards and recommended practices, and calls for comments. These summaries provide the main points of circular letters issued in the prior month, as well as important implementation deadlines.

For access to the complete circular letter, please go to my.aar.org/circulars. Circular letters are a fee-based service provided by the AAR’s Transportation Technology Center Incorporated (TTCI). You may subscribe online at publications@aar.com or call 719.584.0538.

Implementation Circulars

C-13912

Implementation of Revisions to MSRP Section N, Specification M-970, Condition-Based Certification of Multi-Level Auto Rack Cars

Issued: December 10, 2021

Effective: December 10, 2021

The Specially Equipped Freight Car Committee is implementing revisions to Specification M-970, Section 2.2.6. This revision will require all auto racks at certification to be equipped with low-profile securement systems that have been approved since January 1, 2010. Specification M-970 are now implemented and effective immediately and will be incorporated in the next issue of MSRP Section N. In the interim, please insert the circular attachment into your copy of MSRP Section N and be governed accordingly.

CPC-1386

Amendment to CPC-1376 Regarding Hydrostatic Leak Testing

Issued: December 17, 2021

Effective: The date of republication of AAR M-1002 specification.

The sole purpose of this CPC is to notify the industry that on December 7, 2021, during the AAR Tank Car Committee (TCC) teleconference, the committee agreed to delay the January 1, 2022, requirement for each facility that performs hydrostatic leak testing to incorporate HLT into their NDT program because the committee has not completed their review of the hydrostatic test procedures in Appendix D of M-1002.

CPC 1376 has been amended as follows: Each facility that performs hydrostatic leak testing must incorporate HLT into their NDT program no later than the date of republication of AAR M-1002 specification.

C-13918

IMPLEMENTED, AAR Manual of Standards and Recommended Practices (MSRP), Section K-II Locomotive Electronics and Train Consist System Architecture, Specification M-9155.V2.5

Issued: December 20, 2021

Effective: December 20, 2021

Specification M-9155.V2.5 describes functional requirements in sufficient detail and accuracy to support technical proposals to develop an LCCM standalone device or to develop the LCCM function as part of the OEM locomotive control system. This document contains the narrative describing how an Energy Management application may interact with an LCCM as the Controlling Application (it does not contain Energy Management application requirements). Specification M-9155.V2.5, attached to the circular, are now implemented and will be incorporated in the next issue of the MSRP, Section K-II Locomotive Electronics and Train Consist System Architecture. In the interim, please insert the Circular in your copy of the MSRP Section K-II and be governed accordingly.

C-13917

IMPLEMENTED, AAR Manual of Standards and Recommended Practices (MSRP), Section K-IV Office Architecture and Railroad Electronics Messaging, Standard S-9361.V3.1

Issued: December 20, 2021

Effective: December 20, 2021

S-9361.V3.1 contains messages passed between the Positive Train Control (PTC) Office Segment and the Locomotive Segment, and messages passed between the Wayside Status Relay Service (WSRS) and the Locomotive Segment. Standard S-9361.V3.1, attached to the circular, are now implemented, and will be incorporated in the next issue of the MSRP, Section K-IV Office Architecture and Railroad Electronics Messaging. In the interim please insert the Circular in your copy of the MSRP Section K-IV and be governed accordingly.

C-13916

IMPLEMENTED, AAR Manual of Standards and Recommended Practices (MSRP), Section K-IV Office Architecture and Railroad Electronics Messaging, Standard S-9353.V1.1

Issued: December 20, 2021

Effective: December 20, 2021

Standard S-9353.V1.1 contains definitions of data elements used in messages exchanged between applications. Producer application developers are expected to check this data dictionary when constructing new messages. Consumer application developers can use this data dictionary to interpret the contents of messages. This document also contains a description of the categories into which data elements are placed, the attributes of data elements, the types of data elements, and how these data elements are used. Standard S-9353.V1.1, attached to the circular, are now implemented, and will be incorporated in the next issue of the MSRP, Section K-IV Office Architecture and Railroad Electronics Messaging. In the interim please insert the Circular in your copy of the MSRP Section K-IV and be governed accordingly.

Call for Comment

C-13913

Solicitation of Comments for Revisions to MSRP Section C, CAR CONSTRUCTION FUNDAMENTALS AND DETAILS, Standard S-2045 Remote Monitoring Equipment, Installation. Revision of requirements.

Issued: December 13, 2021

Effective: 30 days for comment.

Extensive changes are proposed to the document to better meet industry needs and to establish clear and limited requirements for Remote Monitoring Equipment (RME). The AAR Equipment Engineering Committee (EEC) would like to call attention to paragraph 3.1 as it states that RME and installation must be minimally intrinsically safe to Division 1 per Underwriters Laboratories publication UL 913 and Factory Mutual Research Corporation publication FM 3610. EEC’s intent with this requirement is to allow approved installations of RME on all cars without consideration for their operating environment. Alternately, the industry would require some form of tracking and handling to ensure that cars with non-intrinsically safe devices do not enter certain facilities. Car owners and other users of RME are encouraged to forward this circular to suppliers of RME to help ensure that all suppliers can comment. A copy of the draft and current version of S-2045 is attached to the circular.

C-13920

Solicitation of Comments for Revisions to MSRP Section C CAR CONSTRUCTION FUNDAMENTALS AND DETAILS: Proposed new Standard “S-2057 Draft Arrangements, 24 5/8-in. Pocket” and retirement of existing standards S-239, S-243, and S-245

Issued: December 21, 2021

Effective: 30 days for comment.

The purpose of this circular letter is to solicit comments for revisions proposed to Section C CAR CONSTRUCTION FUNDAMENTALS AND DETAILS. Attached is proposed new Standard S-2057 Draft Arrangements, 24 5/8-in. Pocket. The AAR Equipment Engineering Committee’s (EEC) intent is to consolidate the following 24 5/8-in. pocket standards into one. These three existing standards would be retired upon implementation of S-2057:

- S-239 Arrangement E60 Coupler Design 24 5/8-in. Draft Gear Pocket Striker Applied by Welding

- S-243 Draft Arrangement, E68 Coupler, 24 5/8-in. Pocket

- S-245 Draft Arrangement, F70 Coupler, 24 5/8-in. Pocket—Striker Applied by Welding

Additional draft arrangements for 24 5/8-in pockets (including rotary couplers and draft gears with more than 3 ¼ inch travel) will be added soon.

The EEC expects to implement additional standards for pockets other than 24 5/8 inches with nonhydraulic draft systems. Ultimately all pockets will be arranged in a set of standards with a format like S-2057. The approach sets forth requirements that suppliers can follow which will allow systems to be easily incorporated into car designs. The proposed draft is attached to the circular.

C-13921

Solicitation of Comments for Revisions to MSRP Section T, Specification, M-1004 Specification for Fuel Tenders

Issued: December 31, 2021

Effective: 30 days for comment.

The purpose of the circular is to seek industry comments to a revised M-1004 Specification for Fuel Tenders. The resulting M-1004 Specification and accompanying standards will allow new fuel tenders to be qualified for unrestricted interchange in freight service. These AAR publications identify the tender’s structural design requirements, operating performance, crashworthiness, fuel interfaces needed to supply natural gas to dual-fuel locomotives, and interfaces needed to load the tender with fuel. The proposed draft is attached to the circular.

Notice of Circulars

C-13910

Informational Circular, Revisions to Office Manual, Rule 94

Issued: December 6, 2021

Effective: December 6, 2021

Revisions to Rule 94 “Equipment Health Management Systems (EHMS),” have been reviewed and approved. The changes pertain to criteria for Reads traceability and detectors. The entire text of the revision is included in the circular. These changes will be included in the January 2022 release of the Field Manual.

C-13911

Notice of Implementation to Edit the Figures 154-A and 154-B: Steel Tubing on Bulkhead Flatcars – Section 2 of the AAR Open Top Loading Rules Manual (OTLR)

Issued: December 10, 2021

Effective: December 10, 2021

The AAR’s Open Top Loading Rules Committee (OTLRC) has approved to implement revisions to figures 154-A and 154-B. The entire text of the revision is included in the circular. The implementation of these revisions is effective immediately and will be included in the next edition of the AAR’s OTLR Manual. In the interim, please insert the circular attachment for Figures 154-A and 154-B from Section 2 and be governed accordingly. Carriers are asked to ensure that copies of this circular letter are distributed to all concerned shippers and railroad personnel for their attention and guidance.

C-13915

Informational Circular, Canadian Car Repair Facility Labor Rate – Effective January 1, 2022

Issued: December 15, 2021

Effective: December 15, 2021

The Canadian Car Repair Facility Labor Rate, effective January 1, 2022, is $228.29 CAD. This represents an increase of $22.23 CAD (10.8%) from the calculation for October 1, 2021. The change will be reflected in the January 1, 2022, release of the Canadian Price Master.

C-13914

Informational Circular, Car Repair Facility Labor Rate – Effective January 1, 2022

Issued: December 15, 2021

Effective: December 15, 2021

The Car Repair Facility Labor Rate, effective January 1, 2022, is $149.27. This represents an increase of $17.54 (13.3%) from the calculation for October 1, 2021. The change will be reflected in the January 1, 2022, release of the AAR Office Manual.

C-13919

January 2022 Field and Office Manuals, Summary of Comments and Implementation Details

Issued: December 21, 2021

Effective: December 21, 2021

In November 2021, several Circular Letters soliciting comments to proposed rule changes for the Field Manual were issued. In addition, several letters were issued that advised of approved changes that would become effective on January 1, 2022. The circular provides a recap of those letters seeking industry comment, an indication of comments received (if any), consideration and implementation details.

Greenbrier’s Response to COVID-19

As this challenging time continues, Greenbrier would like to provide an update on operations and our continued dedication to our customers, employees, and communities. As rail workers and contractors are designated “Essential Critical Infrastructure Workers”, Greenbrier’s manufacturing and repair facilities are fully operational. Our office teams are available as well, though most are working remotely. We encourage you to contact your Greenbrier representative if you have any questions or concerns—we are here for you.

For more information, visit our webpage that details Greenbrier’s response to COVID-19.

Greenbrier’s Regulatory Services Group

Peace of mind for your business.

The Regulatory Management Group, led by James Rader, provides regulatory, engineering, process consulting and advocacy support to the railcar repair industry and the petrochemical rail shipper community.

- ASNT Level III Subscription Services

- DOT Compliance Assessments (Corporate and Plant)

- DOT Hazardous Materials Training (Corporate and Plant)

- Expert Witness Services in Rail-Related Litigation

- Federal Government Claims Mitigation (e.g. FRA and PHMSA)

- Nondestructive Testing Programs

- Quality Assurance Program Development

- Regulatory Counsel and Policy Advocacy

- Railcar Repair Management (Design Review, Drawings, Engineering and AAR Approval Administration)

- Tank Car Reliability and Maintenance Programs (49 CFR Subpart F of Part 180)

- Tank Car Maintenance Data Collection and Reliability Performance Analysis

- Welding Program Development

For inquiries about these summaries or any of our services, please reach out to: regulatoryservices@gbrx.com

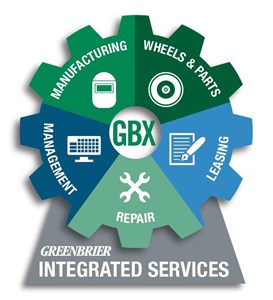

About Greenbrier Management Services (GMS)

Greenbrier Management Services (GMS) is North America’s most comprehensive railcar management solutions provider. GMS manages nearly 400,000 railcars and has invested over 20 years in developing technology, processes, and people to provide the best railcar management products and services in the industry. GMS is powered by proprietary software and the best subject matter experts in the railcar business.

COMPREHENSIVE. INTEGRATED. VALUE.

Combined, these two vitally important capabilities are able to deliver world-class solutions to every type of customer, from Class I railroads, lessors and industrial shippers to financial investors. GMS brings broad expertise to cover nearly any railcar management need that customers may have and its integrated solutions and reporting can be customized for any customer function or management need.