About AAR Circular Letters

Circular letter summaries are produced monthly by Greenbrier’s Regulatory Management team, a division of Greenbrier Management Services Group.

AAR circular letters provide information of general applicability to the railroad industry, including proposed and final rules, revisions, standards and recommended practices, and calls for comments. These summaries provide the main points of circular letters issued in the prior month, as well as important implementation deadlines.

For access to the complete circular letter, please go to my.aar.org/circulars. Circular letters are a fee-based service provided by the AAR’s Transportation Technology Center Incorporated (TTCI). You may subscribe online at publications@aar.com or call 719.584.0538.

Implementation Circulars

C-13933

Implementation of Revisions to MSRP Section T INTEROPERABLE FUEL TENDERS FOR LOCOMOTIVES, Specification M-1004, SPECIFICATION FOR FUEL TENDERS

Issued: February 9, 2022

Effective: February 9, 2022

Revised specification M-1004, attached to the circular, is implemented and effective immediately. This modification will be incorporated in the next issue of the Manual of Standards and Recommended Practices, Section T. Please update your library and be governed accordingly

Call for Comment

C-13931

Solicitation of Comments: Revisions to MSRP F, Sensors, S-920, Component Identification Bar Code Standard – Sections 10 Wheel Set CID Labels

Issued: February 3, 2022

Effective: 30 days for comment.

The proposed change includes the addition of a new element (C012) to the wheel set data glossary to allow for a new, optional, derived field, indicating on the wheelset CID label in human readable text whether the wheels are new (N) or turned (T).

The proposed change also includes a modification to data element (C117) on the wheel data glossary to strike text referencing a future acknowledgement of this status in the wheelset data glossary and adds a statement that values for C012 and C117 must be the same. The draft is attached to the circular for review.

C-13932

DRAFT S-9009.V1.0 – Certificate Requirements is available for review and comment, in support of AAR’s MSRP – Section K-V, Electronics Environmental Requirements and Systems Management.

Issued: February 7, 2022

Effective: 10 days for comment.

The document provides guidance for managing X.509 certificates to ensure interoperability and minimum interoperable security practices. The scope of this document includes: the minimum requirements for the attributes for end entry certificates used by PTC to provide the appropriate level identity assurance for interoperable purposes, the process for validating the certificate, the minimum requirements for certificate authorities issuing certificates and the minimum requirements for managing revocation of certificates.

SharePoint access can be found at www.railinc.com.

C-13934

DRAFT S-9451.V2.0 – ITCSM Common Systems Management Requirements is available for review and comment in support of AAR’s MSRP – Section K-V, Electronics Environmental Requirements and Systems Management.

Issued: February 9, 2022

Effective: 30 days for comment.

The purpose of the document is to describe the L1 requirements established for the Interoperable Train Control Systems Management (ITCSM) system. These requirements are based on information and specifications provided by the Interoperable Train Control (ITC) technical teams using the systems management principles defined by the ITC Architecture team. The goal of the ITCSM is to keep ITC systems operational. ITCSM shall do the following for ITC assets: establish a security infrastructure for distributing sensitive data, enable interoperability, enforce access controls, enable over-the-air updates (e.g., configuration, software), and support problem diagnosis through the generation and distribution of notifications and logs.

SharePoint access can be found at www.railinc.com.

C-13935

Solicitation of Comments for Revisions to MSRP Section S, CASTING DETAILS, Specification M-220, Casting Component Nondestructive Testing Requirements, regarding updates to NDT requirements

Issued: February 11, 2022

Effective: 30 days for comment.

The Coupling System and Truck Castings Committee (CSTCC) is proposing changes to M-220 as follows:

- Light source requirement for liquid penetrant testing changed to 100 footcandles.

- Inspection area of rib openings on truck bolsters is defined as rib opening plus ½ inch around perimeter.

- Yoke placements of Figure C.3 changed.

- Combined two placements into single placement across the end of unit guide.

- Corrected hash marks at turn of spring seat.

- Extended yoke placement markers at turn of spring seat.

- Images demonstrating yoke placements were updated.

- Various editorial changes made for clarity.

The draft is attached to the circular for review.

C-13936

Solicitation of Comments for Revisions to MSRP Section S, CASTING DETAILS, Specification M-211, Foundry and Product Approval Requirements for the Manufacture of Couplers, Coupler Yokes, Knuckles, Follower Blocks, and Coupler Parts, regarding updates to Ap

Issued: February 22, 2022

Effective: 30 days for comment.

The Coupling System and Truck Castings Committee (CSTCC) is proposing changes to M-211 as follows:

- References to older non-reduced slack E-type couplers and knuckles were removed from Appendix A.

- References to older EF-type couplers were removed from Appendix A.

- References to M-216 qualified E-type and F-type knuckles were added to Appendix A.

- Style L drawing was added to Appendix E.

- Style L and Combination M were added to Appendix F column 11.

All manufacturers currently only produce the reduced slack version of couplers and knuckles and therefore there are no expected increases in cost to the industry as a result of the proposed changes.

Notice of Circulars

CPC-1388

Notice to Tank Car Facilities Regarding Implementation of Adverse Audit Finding Report Online Tool

Issued: February 22, 2022

Effective: April 4, 2022

The AAR is deploying a new Adverse Audit Finding Report (AAFR) online tool for tank car facilities. This tool will reside in the existing AAR online system for facility certification and replaces the AAFR paper and email communication processes between the facility primary point of contact and the accredited/certified lead auditor. The AAFR tool provides enhanced transparency to the AAR online system from time of application through final notification of committee action.

A user guide will be made available within the online system no later than March 1, 2022, and accessible at: https://aar.iirx.net/. AAR will also be offering Demonstration Webinars to showcase the navigation and features of this tool. The webinar schedule is included in the circular.

The use of this online tool becomes effective and mandatory for tank car facility audits performed after April 4, 2022.

Upcoming Events

Railway Age Presents Next-Gen Freight Rail Conference

March 15, 2022

GBX is sponsoring the Next-Gen Freight Rail conference.

Greenbrier’s Response to COVID-19

As this challenging time continues, Greenbrier would like to provide an update on operations and our continued dedication to our customers, employees, and communities. As rail workers and contractors are designated “Essential Critical Infrastructure Workers”, Greenbrier’s manufacturing and repair facilities are fully operational. Our office teams are available as well, though most are working remotely. We encourage you to contact your Greenbrier representative if you have any questions or concerns—we are here for you.

For more information, visit our webpage that details Greenbrier’s response to COVID-19.

Greenbrier’s Regulatory Services Group

Peace of mind for your business.

The Regulatory Management Group, led by James Rader, provides regulatory, engineering, process consulting and advocacy support to the railcar repair industry and the petrochemical rail shipper community.

- ASNT Level III Subscription Services

- DOT Compliance Assessments (Corporate and Plant)

- DOT Hazardous Materials Training (Corporate and Plant)

- Expert Witness Services in Rail-Related Litigation

- Federal Government Claims Mitigation (e.g. FRA and PHMSA)

- Nondestructive Testing Programs

- Quality Assurance Program Development

- Regulatory Counsel and Policy Advocacy

- Railcar Repair Management (Design Review, Drawings, Engineering and AAR Approval Administration)

- Tank Car Reliability and Maintenance Programs (49 CFR Subpart F of Part 180)

- Tank Car Maintenance Data Collection and Reliability Performance Analysis

- Welding Program Development

For inquiries about these summaries or any of our services, please reach out to: regulatoryservices@gbrx.com

About Greenbrier Management Services (GMS)

Greenbrier Management Services (GMS) is North America’s most comprehensive railcar management solutions provider. GMS manages nearly 400,000 railcars and has invested over 20 years in developing technology, processes, and people to provide the best railcar management products and services in the industry. GMS is powered by proprietary software and the best subject matter experts in the railcar business.

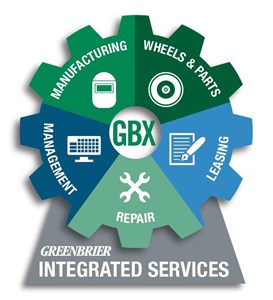

COMPREHENSIVE. INTEGRATED. VALUE.

Combined, these two vitally important capabilities are able to deliver world-class solutions to every type of customer, from Class I railroads, lessors and industrial shippers to financial investors. GMS brings broad expertise to cover nearly any railcar management need that customers may have and its integrated solutions and reporting can be customized for any customer function or management need.