About AAR Circular Letters

Circular letter summaries are produced monthly by Greenbrier’s Regulatory Management team, a division of Greenbrier Management Services Group.

AAR circular letters provide information of general applicability to the railroad industry, including proposed and final rules, revisions, standards and recommended practices, and calls for comments. These summaries provide the main points of circular letters issued in the prior month, as well as important implementation deadlines.

For access to the complete circular letter, please go to my.aar.org/circulars. Circular letters are a fee-based service provided by the AAR’s Transportation Technology Center Incorporated (TTCI). You may subscribe online at publications@aar.com or call 719.584.0538.

CPC-1325 Circular Deep Dive

Please visit Pending Regulatory Changes for Shipping Toxic-by-Inhalation Hazard Materials by Rail for the most up-to-date information on this pressure tank car circular.

Implementation Circulars

C-12894

Car Repair Facility Labor Rate Effective July 1, 2017

Issued: June 2, 2017

Effective: June 2, 2017

The Car Repair Facility Labor Rate, effective July 1, 2017, is $129.76, an increase of $0.02 from the calculation for April 1, 2017.

C- 12902

Implementation of Figures 1-A and 1-C– Section 3 AAR Open Top Loading Rules Manual (OTLR)

Issued: June 9, 2017

Effective: June 9, 2017

The AAR’s Open Top Loading Rules Committee (OTLRC) has re-implemented figures 1-A and 1-C – Section 3 of the AAR Open Top Loading Rules (these figures were not included in the 2017 edition of Section 3). The implementation of this revision to Section 3 is effective immediately and will be included in the next edition of the AAR’s OTLR Manual. In the interim, please insert the circular attachment for Figures 1-A and 1-C in your copy Section 3 and be governed accordingly. Carriers are asked to ensure that copies of this circular letter are distributed to all concerned shippers and railroad personnel for their attention and guidance.

C-12903

Implementation of Revisions to Figures 109 and 109-B– Section 2 AAR Open Top Loading Rules Manual (OTLR)

Issued: June 9, 2017

Effective: June 9, 2017

The AAR’s Open Top Loading Rules Committee (OTLRC) has approved revisions to Figures 109– Section 2 of the AAR Open Top Loading Rules. These changes consolidated Figures 109 and 109-B. Figure 109-B is now archived. The implementation of this revision to Section 2 is effective immediately and will be included in the next edition of the AAR’s OTLR Manual. In the interim, please insert the circular attachment for Figures 109 and 109-B in your copy Section 2 and be governed accordingly. Carriers are asked to ensure that copies of this circular letter are distributed to all concerned shippers and railroad personnel for their attention and guidance.

C-12905

Implementation of Revisions to MSRP Section E, BRAKES AND BRAKE EQUIPMENT, Standard S-431, Brake Shoe High-Friction Composition Type – Limiting Contour, Additional Detail

Issued: June 13, 2017

Effective: June 13, 2017

The implementation of this revision to Standard S-431 is effective immediately. This modification will be incorporated in the next issue of the Manual of Standards and Recommended Practices, Section E. Please update your library and be governed accordingly

C-12917

Implementation of Revisions to Figure 154-B, TUBING, STEEL, SQUARES, RECTANGLES, HOLLOW STRUCTURAL, AND ROUNDS, OVER 12 FT LONG, PACKAGED—BULKHEAD FLATCARS, WITH CUSHIONING DEVICES – Section 2 AAR Open Top Loading Rules Manual (OTLR)

Issued: June 28, 2017

Effective: June 28, 2017

The implementation of this revision to Section 2 is effective immediately and will be included in the next edition of the AAR’s OTLR Manual. In the interim, please insert the circular attachment for Figure 154-B in your copy Section 2 and be governed accordingly. Carriers are asked to ensure that copies of this circular letter are distributed to all concerned shippers and railroad personnel for their attention and guidance.

C-12918

Implementation of Revisions to Figure 14 PLATE OR SLAB, HORIZONTAL – FLATCARS OR BULKHEAD FLATCARS, 66 FT OR LESS – Section 2 AAR Open Top Loading Rules Manual (OTLR) t

Issued: June 28, 2017

Effective: June 28, 2017

The implementation of this revision to Section 2 is effective immediately and will be included in the next edition of the AAR’s OTLR Manual. In the interim, please insert the circular attachment for Figure 14 in your copy Section 2 and be governed accordingly. Carriers are asked to ensure that copies of this circular letter are distributed to all concerned shippers and railroad personnel for their attention and guidance.

C-12919

Implementation of Revisions to Figure 14 PLATE OR SLAB, HORIZONTAL – FLATCARS OR BULKHEAD FLATCARS, 66 FT OR LESS – Section 2 AAR Open Top Loading Rules Manual (OTLR)

Issued: June 28, 2017x

Effective: June 28, 2017

The implementation of this revision to Section 2 is effective immediately and will be included in the next edition of the AAR’s OTLR Manual. In the interim, please insert the circular attachment for Figure 14 in your copy Section 5 and be governed accordingly. Carriers are asked to ensure that copies of this circular letter are distributed to all concerned shippers and railroad personnel for their attention and guidance.

Solicitation of Comments Circulars

C-12904

Solicitation of Comments for new Proposed New MSRP Section T, M-1004 Specification for Fuel Tenders

Issued: June 10, 2017

Effective: 30 days for comments

The Natural Gas Fuel Tender Technical Advisory Group was formed in October, 2012, with the mission to develop AAR Fuel Tender Specifications and Standards to support the use of natural gas (methane) as an alternative locomotive fuel. Membership includes Railroads and AAR-TTCI staff, along with FRA, PHMSA, and supplier observer-participants. The resulting draft M-1004 Specification and accompanying draft standards apply to new natural gas fuel tenders to be qualified for free, unrestricted interchange freight service. The AAR documents identify the tender’s structural design requirements, operating performance, crashworthiness, fuel interfaces needed to supply natural gas to dual-fuel locomotives, and interfaces needed to load the tender with fuel. The proposal is attached to the circular.

C-12906

Solicitation of Comments for Revisions to MSRP Section H, Journal Bearings and Lubrication, M-924, M-934, M-934C, M-942, and S-703, Backing Rings, Grease and Seal Combinations, and Cap Screw Tolerances

Issued: June 13, 2017

Effective: 30 days for comments

The purpose of this circular letter is to solicit comments for proposed revisions to MSRP Section H, Journal Bearings and Lubrication (M-924, M-934, M-934C, M-942, and S-703). The addition of alternative measuring techniques used for adapter manufacturing, updates to the AAR-approved roller bearing backing rings, updates to the AAR-approved roller bearing grease and seal combinations, and the addition of cap screw length tolerances. Proposed revisions are attached to the circular. The proposed revisions do not have costs associated with implementation.

C-12912

Solicitation of Comments for Revisions to MSRP Section G, Wheels and Axles, M-107/M-208, Hardness Mapping and Wheel Marking

Issued: June 19, 2017

Effective: 30 days for comments

The purpose of this circular letter is to solicit comments for proposed revisions to MSRP Section G, Wheels and Axles, M-107/M-208, updating the plate Brinell location and figure, and defining the locomotive wheel stamp location. Proposed revisions are attached to the circular. The proposed revisions do not have costs associated with implementation.

C-12913

Solicitation of Comments for Revisions to MSRP Section H-II, Roller Bearing Manual, S-721, Brinelling Description

Issued: June 19, 2017

Effective: 30 days for comments

The purpose of this circular letter is to solicit comments for proposed revisions to MSRP Section H-II, Roller Bearing Manual, S-721, updating the Brinell description to remove the requirement to de-cage the inner rings that are associated with unacceptable outer rings as a result of 10 or more Brinell tests. Proposed revisions are attached to the circular. The proposed revisions do not have costs associated with implementation.

C-12914

Solicitation of Comments for Revisions to Figures 247 and 134-A– Section 2 AAR Open Top Loading Rules Manual (OTLR) t

Issued: June 20, 2017

Effective: 30 days for comments

The OTLRC requests comments from the industry regarding the merging of Figure 134-A “Pipe, Steel, Uncoated, 14 In. O.D., 40 Ft Long, Two Piles—Flatcars, 89 Ft Long, With Cushioning Devices” and Figure 247 “Pipe, Steel, Bare, Coated, or Wrapped, 14 In. To 72 In. O.D., 40 Ft Long, Two Piles—Flatcars, 85 Ft to 89 Ft.” Figure 134-A will be archived (duplicate). Proposed revisions are attached to the circular. Carriers are asked to ensure that copies of this circular letter are distributed to all concerned shippers and railroad personnel for their attention and guidance.

C-12915

Solicitation of Comments, Revisions to Field Manual, Rule 23, Articulator Connectors

Issued: June 21, 2017

Effective: 30 days for comments

On May 8, 2017, C-12866 was issued requesting comments on the proposed Rule 23 for Articulator Connectors. Multiple comments were received, reviewed and approved for implementation on July 1, 2017. The comments received prompted changes to 23.E and 23.F. Proposed revisions to Rule 23 are attached to the circular for comment.

C-12916

July 2017 Field and Office Manual, Summary of Comments and Implementation Details

Issued: June 21, 2017

Effective: July 1, 2017

A recap of those letters seeking industry comment, an indication of comments received (if any), consideration and implementation details are included in the circular.

C-12921

Solicitation of Comments for Revisions to MSRP Section S, CASTING DETAILS, Specification M-201, Castings, Steel

Issued: June 29, 2017

Effective: 30 days for comments

This circular letter is soliciting comments for revisions proposed to MSRP Section S, Specification M-201. The Coupling System and Truck Castings Committee (CSTCC) has proposed several changes including the addition of a requirement to grind following air arc defect removal in order to remove carburized layer, the option to conduct additional nondestructive testing, a provision for forced air cooling during normalize or normalize and temper processes, an updated MSRP Compliance Checklist and the removal of an outdated reference to Appendix III of ASTM A255 from the MSRP Compliance Checklist. There are no costs associated with the implementation of these revisions. Proposed revisions are attached to the circular.

C-12922

Solicitation of Comments for Revisions to MSRP Section S, CASTING DETAILS, Specification M-220, Regarding Developer Requirements

Issued: June 29, 2017

Effective: 30 days for comments

This circular letter is soliciting comments for revisions proposed to Section S, Specification M-220, regarding the stocking of spray developer and its application during inspection. With this proposed change, the requirements for having and using spray developer will be based solely on achieving proper visual contrast. There are no costs associated with the implementation of these revisions. Proposed revisions are attached to the circular.

Notice Circulars

C-12895 and C-12920

Remainder 2017 Open Class Registrations for AAR M-1003 Quality Assurance Training Courses: Basic Auditor Training Class & Advanced Auditor Training Class

Issued: June 2, 2017 and June 29, 2017

Effective: N/A

A summary of the current schedule of courses is included in the circular.

C- 12896

Informational Circular, Revisions to Field Manual, Rule 5 – Revised June 6, 2017

Issued: June 5, 2017

Effective: June 5, 2017

At the April 2017 meeting of the Arbitration and Rules Committee, a proposal was advanced by the BSC, to revise Rule 5 to address concerns with improperly installed flexible pipe. The revision was approved and the text is included in the summary. These revisions will be included in the July 2017 update of the Field Manual.

C-12897

Informational Circular, Revisions to Field Manual, Rules 1 and 41, MD-115 Submission

Issued: June 5, 2017

Effective: June 5, 2017

At the April 2017 meeting of the Arbitration and Rules Committee, a proposal as advanced by the WABL Committee, to revise Field Manual Rules 1 and 41. The revision was reviewed and approved and the text is included in the summary. These revisions will be included in the July 2017 update of the Field Manual.

C-12898

Informational Circular, Revisions to Field Manual, Rule 4

Issued: June 5, 2017

Effective: June 5, 2017

At the April 2017 meeting of the Arbitration and Rules Committee, a proposal was advanced by the BSC, to revise Rule 4 concerning slope sheet mount Job Codes. The revision was approved and the text is included in the summary. These revisions will be included in the July 2017 update of the Field Manual.

C- 12899

Informational Circular, Revisions to Field Manual, Rule 44.E

Issued: June 6, 2017

Effective: June 6, 2017

At the April 2017 meeting of the Arbitration and Rules Committee, a proposal was advanced by the WABL Committee to revise Field Manual Rule 44.E. The revision was approved and the text is included in the summary. These revisions will be included in the July 2017 update of the Field Manual.

C- 12900

Informational Circular, Revisions to Field Manual, Rule 95.B.5.e

Issued: June 6, 2017

Effective: June 6, 2017

At the April 2017 meeting of the Arbitration and Rules Committee, a proposal was advanced by the Specially Equipped Freight Car Committee, to revise Rule 95.B.5.e. The revision was approved and the text is included in the summary. These revisions will be included in the July 2017 update of the Field Manual.

C-12901

Informational Circular, Revisions to Office Manual, Rule 112.G.7

Issued: June 6, 2017

Effective: June 6, 2017

At the April 2017 meeting of the Arbitration and Rules Committee, a proposal was advanced by the Car Repair Billing Committee, to revise Office Manual Rule 112.G.7 to a new 112.G.7.c. The revision was approved and the text is included in the summary. These revisions will be included in the July 2017 update of the Field Manual.

C-12907

Informational Circular, Revisions to Field Manual, Rule 36.B Correct Repair Chart and 36.E

Issued: June 13, 2017

Effective: June 13, 2017

At the April 2017 meeting of the Arbitration and Rules Committee, a proposal was advanced by the WABL Committee to revise Field Manual Rule 36.B and 36.E. The revision was approved and the text is included in the summary. These revisions will be included in the July 2017 update of the Field Manual.

C-12908

Informational Circular, Revisions to Field Manual, Rule 53, Running Boards

Issued: June 13, 2017

Effective: June 13, 2017

At the April 2017 meeting of the Arbitration and Rules Committee, a proposal was advanced by the Equipment Engineering Committee to revise Rule 53.B.1.a and 53.B.1.d. The revision was approved and the text is included in the summary. These revisions will be included in the July 2017 update of the Field Manual.

C-12909

Informational Circular, Revisions to Field Manual, Rule 80, Painting and Stenciling

Issued: June 13, 2017

Effective: June 13, 2017

At the April 2017 meeting of the Arbitration and Rules Committee, a proposal was advanced by the EEC, to revise Rules 80.B and 80.E. The revision was approved and the text is included in the summary. These revisions will be included in the July 2017 update of the Field Manual.

C-12910

Informational Circular, Revisions to Field Manual, Rule 41.E, Use of Why Made Code 48

Issued: June 14, 2017

Effective: June 14, 2017

At the April 2017 meeting of the Arbitration and Rules Committee, a proposal was advanced by the WABL Committee to clarify the use of Why Made Code 48. The revision was approved and the text is included in the summary. These revisions will be included in the July 2017 update of the Field Manual.

C-12911

Informational Circular – Field Manual Appendix D – Information request, Tank Car Bottom Outlet & Safety Valves

Issued: June 15, 2017

Effective: June 15, 2017

The Appendix D task force is looking to assemble a complete comprehensive list of all types, styles, and sizes of bottom outlet valves and safety valves specific to each manufacturer. This information is to be published in Appendix D of the AAR Field Manual and is intended to be used in establishing and maintaining all codification used in the railroad industry Car Repair Billing System that will identify component specific information in an effort to create standardization in coding throughout the industry. If you are a manufacturer or supplier of either of these components please contact the Appendix D Task Force with information pertinent to these tank car valves. Contact information is included in the circular.

Greenbrier’s Regulatory Services Group

Peace of mind for your business.

The Regulatory Management Group, led by James Rader, provides regulatory, engineering, process consulting and advocacy support to the railcar repair industry and the petrochemical rail shipper community.

- ASNT Level III Subscription Services

- DOT Compliance Assessments (Corporate and Plant)

- DOT Hazardous Materials Training (Corporate and Plant)

- Expert Witness Services in Rail-Related Litigation

- Federal Government Claims Mitigation (e.g. FRA and PHMSA)

- Nondestructive Testing Programs

- Quality Assurance Program Development

- Regulatory Counsel and Policy Advocacy

- Railcar Repair Management (Design Review, Drawings, Engineering and AAR Approval Administration)

- Tank Car Reliability and Maintenance Programs (49 CFR Subpart F of Part 180)

- Tank Car Maintenance Data Collection and Reliability Performance Analysis

- Welding Program Development

For inquiries about these summaries or any of our services, please reach out to: regulatoryservices@gbrx.com

About Greenbrier Management Services (GMS)

Greenbrier Management Services (GMS) is North America’s most comprehensive railcar management solutions provider. GMS manages nearly 400,000 railcars and has invested over 20 years in developing technology, processes, and people to provide the best railcar management products and services in the industry. GMS is powered by proprietary software and the best subject matter experts in the railcar business.

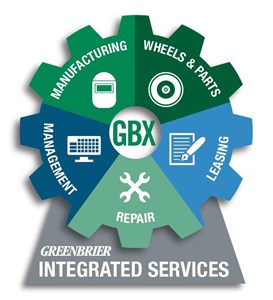

COMPREHENSIVE. INTEGRATED. VALUE.

Combined, these two vitally important capabilities are able to deliver world-class solutions to every type of customer, from Class I railroads, lessors and industrial shippers to financial investors. GMS brings broad expertise to cover nearly any railcar management need that customers may have and its integrated solutions and reporting can be customized for any customer function or management need.