h2>About AAR Circular Letters

Circular letter summaries are produced monthly by Greenbrier’s Regulatory Management team, a division of Greenbrier Management Services Group.

AAR circular letters provide information of general applicability to the railroad industry, including proposed and final rules, revisions, standards and recommended practices, and calls for comments. These summaries provide the main points of circular letters issued in the prior month, as well as important implementation deadlines.

For access to the complete circular letter, please go to my.aar.org/circulars. Circular letters are a fee-based service provided by the AAR’s Transportation Technology Center Incorporated (TTCI). You may subscribe online at publications@aar.com or call 719.584.0538.

Implementation Circulars

C-13594

Implementation of Revisions to MSRP Section G-II, WHEEL AND AXLE MANUAL, RP-631, MD-11 Reporting and Bearing External Inspection

Issued: June 2, 2020

Effective: June 2, 2020

RP-631 is now implemented and effective immediately. The revision, attached to the circular, will be incorporated in the next issue of the Manual of Standards and Recommended Practices, Section G-II. Please update your library and be governed accordingly.

CPC-1368

Notification to Tank Car Facilities on Submittal of AAR M-1002 Exhibit T-1 by July 31, 2020

Issued: June 2, 2020

Deadline: July 31, 2020

The AAR BOE requests that each TC facility provide the M-1002 Exhibit T-1 form by July 31, 2020 in order to facilitate planning and scheduling of AAR M-1002/M-1003 2020 audits. The form should be submitted to: chris_jester@aar.com. The current version of the Exhibit T-1 version 2.0 is attached to the circular.

C-13595

Implementation of Revisions to MSRP Section L, LETTERING AND MARKING OF CARS, Standard S-910, Marking of Freight Cars, Complete revision of the Standard.

Issued: June 3, 2020

Effective: June 3, 2020

Standard S-910, attached to the circular, is now implemented and effective immediately. The modifications will be incorporated in the next issue of the Manual of Standards and Recommended Practices, Section C (section L will eventually be retired). Please update your library and be governed accordingly.

C-13600

Implementation of Revisions to the Manual of Standards and Recommended Practices (MSRP), Section M, LOCOMOTIVES AND LOCOMOTIVE INTERCHANGE EQUIPMENT: Standard S-591 Locomotive System Integration Operating Display

Issued: June 4, 2020

Effective: June 4, 2020

The revised S-591 standard, attached to the circular, is now implemented and effective immediately. The revisions will be incorporated in the next issue of the Manual of Standards and Recommended Practices, Section M. Please update your library and be governed accordingly.

CPC-1370

Stub Sill Reinforcing Pad Inspection of Certain ARI-Built Tank Cars

Issued: June 23, 2020

Effective: June 23, 2020

Maintenance Advisory: Severity Code 06 – AAR Defined

Certain tank cars built by ARI-Marmaduke (ARIA) equipped with a reinforcing pad at the inboard end of the stub sill, require inspection at a certified TC facility no later than the next qualification, not to exceed 10 years.

In accordance with Interchange Rule 125, equipment owners are to have their cars inspected at an AAR certified TC facility capable of making the inspection and repair. Inspections to this Advisory must be performed no later than the next tank qualification date. Maintenance activity codes and an inspection summary is included in the summary.

C-13602

Implementation of AAR Manual of Standards and Recommended Practices (MSRP), Section K-VI Railway Data Management and Communications, Standard S-9502.V1.0

Issued: June 26, 2020

Effective: June 26, 2020

Standard S-9502.V1.0, attached to the circular, provides a common track data exchange format for use between railroads, to support track data maintenance activities for interoperable PTC operations. The implementation of revisions will be incorporated in the next issue of the MSRP, Section K-VI Railway Data Management and Communications. In the interim, please insert the Circular in your copy of the MSRP Section K-VI and be governed accordingly.

C-13604

Implementation of Revisions to MSRP Section F, SENSORS, Standard S-920 AAR Component Identification (CID) Bar Code Standard, and MSRP Section B, FREIGHT CAR DRAFT COMPONENTS, Cushioning Devices Specifications M-921B-C-D-E-F. Component Tracking.

Issued: June 29, 2020

Effective: January 1, 2021

Cushioning device manufacturers and reconditioners are required to add approved AAR bar code labels to their product by January 1, 2021.

The implementation of all revisions (attached to the circular) is effective immediately and will be incorporated in the next issues of the Manual of Standard and Recommended Practices, Sections F and B. Please update your library and be governed accordingly.

Early compliance is encouraged as component registration, association, and field registration will be available by October 1, 2020.

Call for Comment

C-13599

Solicitation of Comments for Revisions to MSRP Section T M-1004 Specification for Fuel Tenders, and for Supporting Standards S-5028, S-5029 and S-5030

Issued: June 4, 2020

Effective: 30 days for comment

The proposed M-1004 Specification and accompanying standards will allow new fuel tenders to be qualified for unrestricted interchange in freight service. These AAR publications identify the tender’s structural design requirements, operating performance, crashworthiness, fuel interfaces needed to supply natural gas to dual-fuel locomotives, and interfaces needed to load the tender with fuel. The proposal is attached to the circular.

Notice of Circulars

C-13593

Temporary Relief, MSRP S-6101 and Office Manual Rule 94.8, Detector Calibration

Issued: June 1, 2020

Effective: Until September 30, 2020

Travel restrictions related to COVID-19 have made it difficult to reach detector sites to perform calibrations. Therefore, all registered detectors that were properly functioning, in-service and maintaining original equipment manufacturer (OEM) calibration documentation as of January 1, 2020 shall continue to be designated as calibrated until September 30, 2020. Billing exceptions due to expired calibration dates on wheel impact load detectors (WILD) for repairs made during this period with Why Made Codes 61 and 65 period are not allowed.

Detectors that provide data to Railinc’s Equipment Health Management System (EHMS) will continue to generate data summaries and alerts. All other WABL committee requirements and detector quality monitoring (DQM) processes will remain fully in force.

C-13598

Informational Circular, Canadian Car Repair Facility Labor Rate – Effective July 1, 2020

Issued: June 4, 2020

Effective: July 1, 2020

Effective July 1, the Canadian Car Repair Facility Labor Rate is $184.55 CAD. This rate will be recorded in the upcoming release of the Canadian Price Master. Details concerning exchange rates are included in the circular.

C-13597

Informational Circular, Car Repair Facility Labor Rate – Effective July 1, 2020

Issued: June 4, 2020

Effective: July 1, 2020

Effective July 1, the Car Repair Facility Labor Rate is $141.00 ($0.22 decrease from April 1, 2020). This rate will be recorded in the upcoming release of the AAR Office Manual. Details concerning the calculation of the rate are included in the circular.

C-13596

Schedule for 2020 AAR M-1003 Basic Auditor, Advanced Auditor and Root Cause Analysis Training Classes – June Update 2020

Issued: June 4, 2020

Effective: Schedule included in circular

The AAR Quality Assurance Committee (QAC) has rescheduled some 2020 Basic Auditor, Advanced Auditor and Root Cause Analysis Training classes, and has moved other classes to a Webinar-based training format. Class descriptions and a revised schedule is included in the circular.

CPC-1369

Midland Vacuum Relief Valve Markings

Issued: June 10, 2020

Effective: June 10, 2020

Labels must be acquired and applied to the following models of Midland Vacuum Relief Valve(s):

A-207, 209, 210, 211, 212, 217, 220, and 222.

These models were manufactured before 2018, with a setting of 0.75 psi. The VRV TSB is 20180606 Rev B Issued 7/12/2018. The part number for the supplemental label is 217-012-PL.

The labels can be ordered free of charge by contacting margarette.ward@opwglobal.com.

Information regarding the labels can also be found on Midland’s Technical Service Bulletin page: www.opwglobal.com/products/us/transportation-products/railcar-products/general-purpose-car-products/vacuum-relief-valve-vrvs/-vacuum-relief-valve-vrvs

C-13601

Fall 2020 AAR Technical Committee Meetings

Issued: June 24, 2020

Effective: Committee contact information included in circular

Driven by the context of the Covid-19 pandemic, the AAR has arranged teleconferences or webcasts in lieu of holding face-to-face meetings, for those who participate in and support AAR committees. Unfortunately, teleconferences and webcasts will not be open to public participation. It is hoped that in-person meetings will resume in 2021.

C-13603

Informational Circular, Cost Analysis, Revisions to Field Manual, Rule 4, Over Age Brake Valves

Issued: June 26, 2020

Effective: June 26, 2020

A limited cost analysis is included in the circular. Since a study to measure potential brake performance improvements was not conducted, benefits from the proposed rule change have not been assessed. A table of “net present costs” to the industry is included in the circular.

C-13606

Informational Circular, Cost-Benefit Analysis, Revisions to Field Manual, Rules 3 & 4, 4-Pressure Testing

Issued: June 29, 2020

Effective: June 29, 2020

The revisions to Rules 3 and 4 will allow a repairing party to bill for the retrofit of equipment required to perform a 4-pressure single car test (SCT) as well as require the 4-pressure testing capability for all repair facilities which perform SCTs. A cost-benefit based on the January 2020 AAR Price Master (included in the circular), has been performed to assess the industry impacts.

C-13605

AAR Safety Alert regarding Improperly Secured Tie-down Cables on Centerbeam Cars

Issued: June 29, 2020

Effective: June 29, 2020

This safety alert is being reissued due to ongoing and recurring non-compliance to rules established by AAR Open Top Loading Rules (OTLR) Committee concerning securement of cables on empty centerbeam cars.

General Rule 22.4.3- Section 1 Open Top Loading Rules: All cables must be properly secured per manufacturer’s recommendations prior to car movement.

Carriers are urged to ensure that empty cars being returned by the consignee have their cables properly secured to the railcar. The circular includes a document illustrating both proper and improper cable securement practices. If a car is offered for interchange without the cables properly secured, the car should be rejected out of concern for safety.

C-13607

July 2020 Field and Office Manual, Summary of Comments and Implementation Details

Issued: June 30, 2020

Effective: July 1, 2020

The circular provides a complete list and summary of the circular letters issued in April and May 2020, that solicited industry comment, consideration, and implementation details for rule changes (effective July 1, 2020) in the Field Manual.

Greenbrier’s response to COVID-19

As this challenging time continues, Greenbrier would like to provide an update on operations and our continued dedication to our customers, employees, and communities. As rail workers and contractors are designated “Essential Critical Infrastructure Workers”, Greenbrier’s manufacturing and repair facilities are fully operational. Our office teams are available as well, though most are working remotely. We encourage you to contact your Greenbrier representative if you have any questions or concerns—we are here for you.

For more information, visit our webpage that details Greenbrier’s response to COVID-19.

Greenbrier’s Regulatory Services Group

Peace of mind for your business.

The Regulatory Management Group, led by James Rader, provides regulatory, engineering, process consulting and advocacy support to the railcar repair industry and the petrochemical rail shipper community.

- ASNT Level III Subscription Services

- DOT Compliance Assessments (Corporate and Plant)

- DOT Hazardous Materials Training (Corporate and Plant)

- Expert Witness Services in Rail-Related Litigation

- Federal Government Claims Mitigation (e.g. FRA and PHMSA)

- Nondestructive Testing Programs

- Quality Assurance Program Development

- Regulatory Counsel and Policy Advocacy

- Railcar Repair Management (Design Review, Drawings, Engineering and AAR Approval Administration)

- Tank Car Reliability and Maintenance Programs (49 CFR Subpart F of Part 180)

- Tank Car Maintenance Data Collection and Reliability Performance Analysis

- Welding Program Development

For inquiries about these summaries or any of our services, please reach out to: regulatoryservices@gbrx.com

About Greenbrier Management Services (GMS)

Greenbrier Management Services (GMS) is North America’s most comprehensive railcar management solutions provider. GMS manages nearly 400,000 railcars and has invested over 20 years in developing technology, processes, and people to provide the best railcar management products and services in the industry. GMS is powered by proprietary software and the best subject matter experts in the railcar business.

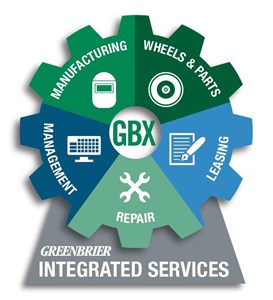

COMPREHENSIVE. INTEGRATED. VALUE.

Combined, these two vitally important capabilities are able to deliver world-class solutions to every type of customer, from Class I railroads, lessors and industrial shippers to financial investors. GMS brings broad expertise to cover nearly any railcar management need that customers may have and its integrated solutions and reporting can be customized for any customer function or management need.