About AAR Circular Letters

Circular letter summaries are produced monthly by Greenbrier’s Regulatory Management team, a division of Greenbrier Management Services Group.

AAR circular letters provide information of general applicability to the railroad industry, including proposed and final rules, revisions, standards and recommended practices, and calls for comments. These summaries provide the main points of circular letters issued in the prior month, as well as important implementation deadlines.

For access to the complete circular letter, please go to my.aar.org/circulars. Circular letters are a fee-based service provided by the AAR’s Transportation Technology Center Incorporated (TTCI). You may subscribe online at publications@aar.com or call 719.584.0538.

Implementation Circulars

C-13941

Implementation of Editorial Revisions to MSRP Section C, CAR CONSTRUCTION FUNDAMENTALS AND DETAILS, Standard S-910 Marking of Freight Cars, regarding update to font

Issued: March 22, 2022

Effective: March 22, 2022

The purpose of the circular letter is to notify the industry of editorial revisions to MSRP Section C, CAR CONSTRUCTION FUNDAMENTALS AND DETAILS, Standard S-910 Marking of Freight Cars. The AAR Font described in paragraph 2.0 has been updated to include additional symbols and characters, and the electronic font file has been updated. The revised Standard S-910, attached, is now implemented and effective immediately. This modification will be incorporated in the next issue of the Manual of Standards and Recommended Practices, Section C. Please update your library and be governed accordingly.

C-13944

Implementation of Revisions to MSRP Section S, CASTING DETAILS, Specification M-220, Casting Component Nondestructive Testing Requirements, regarding updates to NDT requirements

Issued: March 29, 2022

Effective: March 29, 2022

The updates are regarding yoke placement and images:

- Lighting requirements for knuckle testing in Appendix A was updated to 100 footcandles as intended.

- References to “pedestal leg” in Figures C.7 and C.8 were changed to refer to the “underside of tension member.”

Specification M-220 is now implemented and effective immediately. This modification will be incorporated in the next issue of the Manual of Standards and Recommended Practices, Section S. Please update your library with the attached document and be governed accordingly.

C-13945

Implementation of Revisions to MSRP Section S, CASTING DETAILS, Specification M-211, Foundry and Product Approval Requirements for the Manufacture of Couplers, Coupler Yokes, Knuckles, Follower Blocks, and Coupler Parts

Issued: March 29, 2022

Effective: March 29, 2022

The updates are regarding couplers and knuckles in Appendix A – Referenced Figures and Tables and updates to Appendixes E and F Design Features for coupler head lug. Specification M-211 is now implemented and effective immediately. This modification will be incorporated in the next issue of the Manual of Standards and Recommended Practices, Section S. Please update your library with the attached document and be governed accordingly.

C-13948

Implementation of Editorial Revisions to MSRP Section T, INTEROPERABLE FUEL TENDERS FOR LOCOMOTIVES Standard, S-5027 21-Point Control Plug, Cable Assembly and Receptacle (TC-21 Tender Control Cable)

Issued: March 31, 2022

Effective: March 31, 2022

This implementation version incorporates editorial updates to the support standard that would synchronize S-5027 to the changes already approved and implemented within Section T, Specification M-1004 SPECIFICATION FOR FUEL TENDERS.

S-5027, attached to the circular and now implemented and effective immediately. The revised S-5027 standard will be incorporated into the first published issue of the Manual of Standards and Recommended Practices, Section T.

Call for Comment

C-13943

Solicitation for Comments – Revision to MSRP Section N, Specification M-970, Condition-Based Certification of Multi-Level Auto Rack Cars

Issued: March 24, 2022

Effective: 30 days for comment.

The Specially Equipped Freight Car Committee has proposed a revision to MSRP Section N, Specification M-970, Section 2.2.6. This revision will require that tri-level auto racks must be equipped with chock pans/hangars to allow universal chock interchangeability within the chock replacement guidelines group. A summary of the current specification as well as the proposed revisions are included in the circular.

C-13942

Solicitation for Comments – Revision to MSRP Section N, Specification M-950, Universal Wide-Body Tri-Level Fully-Enclosed Auto Rack Car (Low Deck)

Issued: March 24, 2022

Effective: 30 days for comment.

The Specially Equipped Freight Car Committee has proposed revisions to Specification M-950, Section 8.0 – Tie-Down System. The revision proposes to add the requirement that tri-level auto racks must be equipped with chock pans/hangars, which would allow universal chock interchangeability within the chock replacement guidelines group. The summary of the current specification as well as the proposed revisions are included in the circular.

C-13946

Solicitation of Comments for Revisions to MSRP Section G-II, WHEEL AND AXLE MANUAL, S-659, RP-631, RP-632, R-633, and RP-634, Bearing Sampling, NHT Wheels, UT Data Retention, and Gauging Amtrak Wheels

Issued: March 29, 2022

Effective: 30 days for comment.

Revisions include the number of bearings torn down as required for the MD-11 process, adding non-heat treated (NHT) wheels to the list of wheels not returned to service, adding quarterly reporting of wheels rejected for UT indications after turning, clarification of wheel shop mark stamping and gauging the journal fillet, and adding acceptable flange thickness measurements for Amtrak and other passenger wheels. The proposed revisions do not have costs associated with implementation. Drafts are attached to the circular.

C-13947

Solicitation of Comments for Revisions to MSRP Section H-II, ROLLER BEARING MANUAL, S-726, Cone Marking Requirement

Issued: March 29, 2022

Effective: 30 days for comment.

The revisions address who may restore the markings on cones after grinding or machining. The proposed revisions do not have costs associated with implementation. The draft is attached to the circular.

Notice of Circulars

C-13937

Notification of Approval and Pending Implementation of Revisions to MSRP Section C Part II, M-1001, OM Rule 88, and Section C Standard S-286. Car and draft pocket design requirements, effective January 1, 2023.

Issued: March 3, 2022

Effective: January 1, 2023

The purpose of this circular letter is to notify the industry of revisions (effective January 1, 2023) to the following publications:

Section C Part II – Specification M-1001 Design, Fabrication, and Construction of Freight Cars:

Chapter 3 – Material, Body Structure

Chapter 4 – Design

Chapter 6 – General Design and Test Requirements – Tank Cars

Section C – Car Construction Fundamentals and Details, Standard S-286 Free/Unrestricted Interchange For 286,000 Lb Gross Rail Load Cars.

Office Manual Rule 88

On November 18, 2021, Circular Letter C-13907 was issued to solicit comments. No comments were received, and the proposal described is being enacted in its entirety.

The following changes will appear in their respective publications on the effective date of January 1, 2023. Drafts of the pending changes are attached to provide the industry with the guidance and allow actions to be taken now. The new requirements will apply to all newly built cars and certain Rule 88 projects. The circular contains a summary of all changes.

C-13938

Spring 2022 AAR Technical Committee Meetings

The public meetings for the AAR Tank Car Committee have been scheduled from April 20-21 in Oklahoma City, OK). The meetings will be held at the Omni Oklahoma City Hotel.

Information at: https://www.aar.org/event/aar-tank-car-committee-meetings/

The circular also contains a list of dates for the following AAR committee meetings that have been planned for the first half of 2022:

Arbitration & Rules Committee

Asset Health Strategy Committee

Automatic Equipment Identification Committee

Brake Systems Committee

Car Repair Billing Committee

Coupling System & Truck Castings Committee

Damage Prevention and Freight Claims Committee

Engineering Policy Committee

Equipment Engineering Committee

Equipment Health Monitoring Committee

Locomotive Committee

Open Top Loading Rules Committee

Railway Electronics Standards Committee

Signal Committee

Specially Equipped Freight Car Committee

Train Control Communications and Operations Committee

Wheels, Axles, Bearings & Lubrication Committee

Wireless Communications Committee

C-13940

Informational Circular, Canadian Car Repair Facility Labor Rate – Effective April 1, 2022

Issued: March 14, 2022

Effective: March 14, 2022

The Canadian Car Repair Facility Labor Rate, effective April 1, 2022 is $228.49 CAD.

C-13939

Informational Circular, Car Repair Facility Labor Rate – Effective April 1, 2022

Issued: March 14, 2022

Effective: March 14, 2022

The Car Repair Facility Labor Rate, effective April 1, 2022 is $149.27.

Upcoming Events

NARS 2022 Annual Meeting

May 9–11, 2022

Greenbrier’s Lorie Tekorius, President & CEO, is a featured speaker at the next NARS conference in Kansas City, MO.

Greenbrier’s Response to COVID-19

As this challenging time continues, Greenbrier would like to provide an update on operations and our continued dedication to our customers, employees, and communities. As rail workers and contractors are designated “Essential Critical Infrastructure Workers”, Greenbrier’s manufacturing and repair facilities are fully operational. Our office teams are available as well, though most are working remotely. We encourage you to contact your Greenbrier representative if you have any questions or concerns—we are here for you.

For more information, visit our webpage that details Greenbrier’s response to COVID-19.

Greenbrier’s Regulatory Services Group

Peace of mind for your business.

The Regulatory Management Group, led by James Rader, provides regulatory, engineering, process consulting and advocacy support to the railcar repair industry and the petrochemical rail shipper community.

- ASNT Level III Subscription Services

- DOT Compliance Assessments (Corporate and Plant)

- DOT Hazardous Materials Training (Corporate and Plant)

- Expert Witness Services in Rail-Related Litigation

- Federal Government Claims Mitigation (e.g. FRA and PHMSA)

- Nondestructive Testing Programs

- Quality Assurance Program Development

- Regulatory Counsel and Policy Advocacy

- Railcar Repair Management (Design Review, Drawings, Engineering and AAR Approval Administration)

- Tank Car Reliability and Maintenance Programs (49 CFR Subpart F of Part 180)

- Tank Car Maintenance Data Collection and Reliability Performance Analysis

- Welding Program Development

For inquiries about these summaries or any of our services, please reach out to: regulatoryservices@gbrx.com

About Greenbrier Management Services (GMS)

Greenbrier Management Services (GMS) is North America’s most comprehensive railcar management solutions provider. GMS manages nearly 400,000 railcars and has invested over 20 years in developing technology, processes, and people to provide the best railcar management products and services in the industry. GMS is powered by proprietary software and the best subject matter experts in the railcar business.

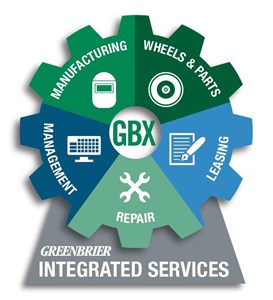

COMPREHENSIVE. INTEGRATED. VALUE.

Combined, these two vitally important capabilities are able to deliver world-class solutions to every type of customer, from Class I railroads, lessors and industrial shippers to financial investors. GMS brings broad expertise to cover nearly any railcar management need that customers may have and its integrated solutions and reporting can be customized for any customer function or management need.