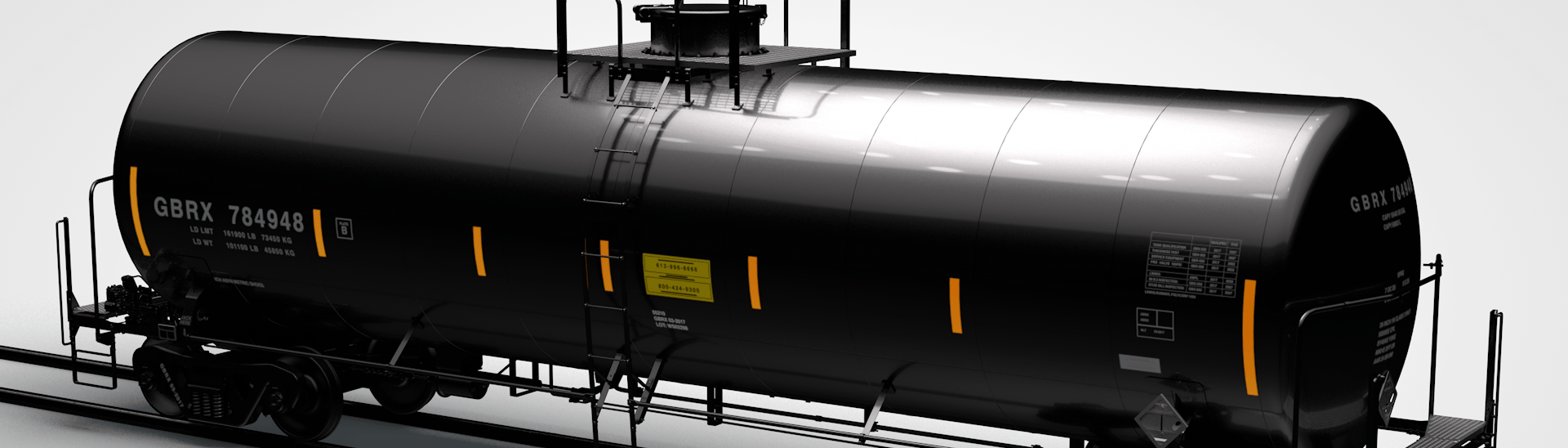

With improved safety features, Greenbrier’s latest chlorine tank car designs aim for zero incidents.

With improved safety features, Greenbrier’s latest chlorine tank car designs aim for zero incidents.

Shipping Chlorine by Rail

Chlorine is an essential chemical building block in today’s modern economy, with applications ranging from water purification to manufacturing and pharmaceuticals. As with most vital commodities, shippers often choose to move chlorine by rail. However, due to its hazardous properties, chlorine poses some unique safety challenges that other commodities, such as crushed rock, do not. For this reason, freight rail is often the preferred mode of transportation.

Freight rail is one of the safest modes of transportation, particularly when it comes to moving hazardous materials. Railcars tend to be much larger than highway freight trucks; so each movement of a hazardous commodity by rail takes multiple freight trucks off congested highways that are prone to more frequent accidents. Additionally, railcar safety features continue to improve, both as a result of enhanced tank car safety regulation and at the demand of conscientious rail shippers.

At Greenbrier, we lead with railcar safety and design innovation at the top of mind. We pride ourselves on anticipating shipper needs and building railcars that go above and beyond the minimum safety requirements. And with new design standards and upcoming regulatory deadlines for chlorine tank cars, Greenbrier’s approach to safety through design is timely.

A Safer, More Efficient Chlorine Tank Car

Our tank car engineers have developed three new chlorine tank cars that exceed the latest DOT 105J600W design requirements outlined by the Association of American Railroads (AAR). Greenbrier optimized each chlorine tank car for a different situation, and each design can be further customized depending on customers’ unique needs.

Chlorine Car Options:

- Our 17,290-gallon tank car uses the most effective tank diameter and is optimized to carry exactly 90 tons of chlorine, the maximum load allowed by current regulations. It is the shortest and lightest of the three chlorine tank cars, and is the most efficient package with respect to the number of 90-ton loads within a train.

- Our 18,044-gallon tank car incorporates an optimized tank diameter, while still meeting the current loading rack requirements of many shippers and consumers. It is the second lightest of the three cars, and was designed to increase flexibility and carrying the potential for car owners should DOT revise the 90-ton loading limit regulation.

- Our 18,440-gallon tank car is optimized to the 286GRL limit, offering maximum capacity potential and loading flexibility should DOT revise the 90-ton loading limit regulation. Due to the increased capacity, this design has a higher lightweight and slightly longer truck centers than the other two cars. However, depending on customer needs, this may be the most efficient design.

All three chlorine tank car options provide enhanced safety features, including:

- Tank pressure rating of 600-pounds per square inch (versus 500-pounds in legacy cars)

- Improved underframe durability: 3-million mile design (versus 1-million used by some builders)

- A combined two inches of ceramic fiber and two inches of fiberglass insulation under an 11-gauge steel jacket (four times as much ceramic thermal protection as tank cars transporting flammable gases or liquids)

- Full-height 1/2″-thick torispherical jacket heads

- 9-MPH rollover protection

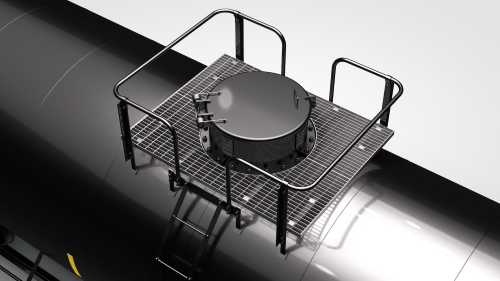

- Single-level top operating platform with mid-rails and toe boards (also accepts two-level)

- Small footprint top fittings housing for more operating platform walk space

- Multiple valve packages available in combination or independently, including sheer-off and traditional valves; 4 angle valves and 1 combination pressure relief device

Many of the safety features outlined above exceed the DOT 105J600W tank car design standard set forth in April 2017. For example, neither the 3-million mile underframe nor the single-level platform are required. Platform mid-rails are available as an option for a safer operating space for the benefit of loading, unloading, inspection and maintenance crews.

Single-level platform increase worker safety.

Strong safety features demand rigorous attention to quality and detail in the manufacturing process. This is an area in which Greenbrier excels, particularly when it comes to tank cars. To date, Greenbrier has had zero (0) failures of its underframe design (data from the Tank Car Integrated Database managed by Sims Engineering).

When it comes to tank cars hauling hazardous materials, safety is our top priority, but not our only one. In addition to high-quality manufacturing and design, we’re focused on maximizing operational efficiency. To that extent, we’ve included many standard and optional features in our chlorine tank car designs that will add value above and beyond getting product safely from point A to point B.

Efficiency-enhancing features on Greenbrier chlorine tank cars include:

- Shorter tank car length for more loading per foot of track

- Large, single-level platform around a smaller top fittings housing provides a roomier work area

- Bolted (vs. welded) top fittings housing for maintainability and access

- Optional GPS system

- Optional Teflon-coated components

- Future load sensor conduit

In combination, we believe that the safety, quality, and operational efficiency gains afforded by these new tank car designs will provide best-in-class value to chlorine shippers interested in upgrading and/or expanding their fleets.

Need more information?

Schedule a visit or call with our engineering and sales team to learn more about our TIH tank car offerings.