About AAR Circular Letters

Circular letter summaries are produced monthly by Greenbrier’s Regulatory Management team, a division of Greenbrier Management Services Group.

AAR circular letters provide information of general applicability to the railroad industry, including proposed and final rules, revisions, standards and recommended practices, and calls for comments. These summaries provide the main points of circular letters issued in the prior month, as well as important implementation deadlines.

For access to the complete circular letter, please go to my.aar.org/circulars. Circular letters are a fee-based service provided by the AAR’s Transportation Technology Center Incorporated (TTCI). You may subscribe online at publications@aar.com or call 719.584.0538.

Implementation Circulars

C-13822

Implementation Circular: MSRP Section F, Sensors, Standard S-6101, Detector Calibration & Validation Requirements: Wheel Impact Load Detector (WILD) Validation Plan

Issued: June 2, 2021

Effective: June 2, 2021

A validation plan for newer Wheel Impact Load Detector (WILD) product offerings has been added to the subject section within Section F (Sensors) and is covered in section 8.0 through 8.8.2. The addition to S-6101 is attached to the circular.

Important Note: The implementation does not include proposed changes to S-6101 (Acoustic Bearing Detector validation requirements) which is currently under review.

C-13823

Implementation of Editorial Updates to MSRP, Section F, S-920, Component Identification Bar Code Standard

Issued: June 4, 2021

Effective: June 4, 2021

The changes to S-921 (attached to the circular) are editorial enhancements intended to reduce the administrative burden on stakeholders relative to barcode label sizes, font details and other miscellaneous items, and to modernize the Bar Code Approval Process (Section 3.0). The revised MSRP Section F will be incorporated into the next issue of the Manual of Standards and Recommended Practices. In the interim, please insert this circular in your copy of MSRP Section F and be governed accordingly.

Important Note: The implementation does not include proposed changes to Section 12 & 13 (Bearing & Axle Lables), which is currently under review.

C-13824

Implementation of Additional/Corrected Editorial Updates to MSRP, Section F, S-920, Component Identification Bar Code Standard

Issued: June 8, 2021

Effective: June 8, 2021

Additional editorial revisions to S-920 clarify, or further modify editorial changes announced via circular C-13823.

Important Note: The copy of the standard attached to this circular supersedes the version released on June 4, 2021 via C-13823. As well, this current implementation does not include proposed changes to Section 12 & 13 (Bearing & Axle Lables) which is currently under review.

C-13826

Implementation of Revisions to MSRP Section S-III, COUPLER AND YOKE DETAILS, Standard S-105, Coupler E Type Detail Parts, regarding making reduced slack components standard

Issued: June 22, 2021

Effective: June 22, 2021

Standard S-105 (attached to the circular) is now implemented and effective immediately. This modification will be incorporated in the next issue of the Manual of Standards and Recommended Practices, Section S-III. Please update your library and be governed accordingly.

C-13831

Implementation Circular – Effective June 28, 2021: Rewrite of Field and Office Manuals Rule 125

Issued: June 23, 2021

Effective: June 28, 2021

Revisions to Rule 125 “Early Warning/Maintenance Advisory (EW/MA) System” have been implemented and are in-effect as of June 28, 2021. A revision document is attached to the circular and must be printed and maintained until the upcoming July 2021 revision to the Field Manual is released.

The terms “Early Warning”, “Maintenance Advisory”, “EW” and “MA” will remain in effect until the upcoming July 2021 release and are synonymous with “Equipment Advisory”. Additionally, the following are also synonymous: MA-0124 = IN-3000, and MA-0063 and EW-5171 = EI-0001.

Important Note: This circular is identified as mandatory in accordance with Field Manual Rule 1.5.b(11) and must be maintained until the upcoming revision of the July 2021 Field Manual is received.

CPC-1383

Implementation of Revisions to MSRP Section C-III, Specification for Tank Cars (M-1002), Appendix B (Docket T91.2.6)

Issued: June 28, 2021

Effective: June 28, 2021

Fastener installation requirements have been updated in Appendix B, attached to the circular, to specify certification conditions for facilities that remove and replace fasteners for service equipment as well as exceptions where replacement of fasteners for service equipment do not require facility certification.

Call for Comment

C-13827

Solicitation of Comments for Revisions to MSRP Section S, CASTING DETAILS, Specifications M-202, M-203, and M-210; regarding reporting to AAR, adding sawcuts, and removing radiography requirements

Issued: June 22, 2021

Effective: 30 days for comment.

CSTCC is removing the requirement for radiography in M-202 and M-203 and adding sawcuts to the corresponding areas of interest in M-210. CSTCC is removing the requirement for manufacturers to report distribution information to AAR since the component tracking system now fulfils that function. No costs to the industry are expected for the proposed changes. A full summary of proposed changes is included the circular.

C-13829

DRAFT S-9152.V2.3 – End-Of-train Communications is available for review and comment. In support of AAR’s MSRP – Section K-II, Locomotive Electronics and Train Consist System Architecture

Issued: June 23, 2021

Effective: 30 days for comment.

The document presents the standard for train information systems, intended to provide additional train handling and safety information in locomotive cabs. The purpose of the standard is to outline various characteristics of devices that transmit information between the rear car and the controlling locomotive cab of freight trains. The proposal is attached to the circular.

Notice of Circulars

C-13825

Informational Circular, Car Repair Facility Labor Rate – Effective July 1, 2021

Issued: June 17, 2021

Effective: July 1, 2021

Effective July 1, 2021, the Car Repair Facility Labor Rate is $130.83. This represents an increase of 19 cents ($0.19) from the calculation for April 1, 2021. The change will be reflected in the July 1, 2021 release of the AAR Office Manual.

CPC-1382

Supplemental Notification to AAR Component ID (CID)

Issued: June 21, 2021

Effective: July 1, 2021

This CPC clarifies the registration and permanent marking requirements for tank car pressure relief valves.

For PRV’s manufactured after December 31, 2003: If the serial number are no longer identifiable on the PRV, the PRV must be scrapped, unless the equipment owner can provide traceability to the serial number through mechanical records (e.g., required documentation per C-III, CH.1) in which case the equipment owner can permit a C5 facility to regenerate and apply the permanent markings to PRV per C-III, Appendix A requirements.

For PRV’s manufactured prior to December 31, 2003: If the month and year of manufacture are no longer identifiable on the PRV, the PRV must be scrapped, unless the equipment owner can provide traceability to other permanent markings through mechanical records (e.g., required documentation per C-III, CH.1) in which case the equipment owner can permit a C5 facility to regenerate and apply the permanent markings to PRV per C-III, Appendix A requirements. For CID registration, the C5 facility would enter “00″ into field D108 (PRV Built Month) and “0000″ into D109 (PRV Built Year).

C-13830

July 2021 Field and Office Manuals, Summary of Comments and Implementation Details

Issued: June 23, 2021

Effective: July 1, 2021.

The circular provides a full summary of letters issued in May 2021 for rule changes that will be implemented in the upcoming July 2021 revision to the Field Manual.

C-13828

Informational Circular, Canadian Car Repair Facility Labor Rate – Effective July 1, 2021

Issued: June 23, 2021

Effective: June 23, 2021

Effective July 1, 2021, the Canadian Car Repair Facility Labor Rate is $204.34 CAD. The change will be reflected in the July 1, 2021 release of the Canadian Price Master.

C-13832

Informational Circular – Changes to CRB Data Exchange Error Code in Conjunction with Rule 112 Revisions

Issued: June 24, 2021

Effective: June 24, 2021

Editorial changes announced via circular C-13823 have been further revised to replace error code 6T with error code 8T “Mandatory Reject.” Error Code 8T will be implemented following the July CRB Data Exchange run.

Greenbrier’s response to COVID-19

As this challenging time continues, Greenbrier would like to provide an update on operations and our continued dedication to our customers, employees, and communities. As rail workers and contractors are designated “Essential Critical Infrastructure Workers”, Greenbrier’s manufacturing and repair facilities are fully operational. Our office teams are available as well, though most are working remotely. We encourage you to contact your Greenbrier representative if you have any questions or concerns—we are here for you.

For more information, visit our webpage that details Greenbrier’s response to COVID-19.

Greenbrier’s Regulatory Services Group

Peace of mind for your business.

The Regulatory Management Group, led by James Rader, provides regulatory, engineering, process consulting and advocacy support to the railcar repair industry and the petrochemical rail shipper community.

- ASNT Level III Subscription Services

- DOT Compliance Assessments (Corporate and Plant)

- DOT Hazardous Materials Training (Corporate and Plant)

- Expert Witness Services in Rail-Related Litigation

- Federal Government Claims Mitigation (e.g. FRA and PHMSA)

- Nondestructive Testing Programs

- Quality Assurance Program Development

- Regulatory Counsel and Policy Advocacy

- Railcar Repair Management (Design Review, Drawings, Engineering and AAR Approval Administration)

- Tank Car Reliability and Maintenance Programs (49 CFR Subpart F of Part 180)

- Tank Car Maintenance Data Collection and Reliability Performance Analysis

- Welding Program Development

For inquiries about these summaries or any of our services, please reach out to: regulatoryservices@gbrx.com

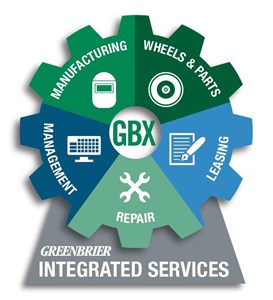

About Greenbrier Management Services (GMS)

Greenbrier Management Services (GMS) is North America’s most comprehensive railcar management solutions provider. GMS manages nearly 400,000 railcars and has invested over 20 years in developing technology, processes, and people to provide the best railcar management products and services in the industry. GMS is powered by proprietary software and the best subject matter experts in the railcar business.

COMPREHENSIVE. INTEGRATED. VALUE.

Combined, these two vitally important capabilities are able to deliver world-class solutions to every type of customer, from Class I railroads, lessors and industrial shippers to financial investors. GMS brings broad expertise to cover nearly any railcar management need that customers may have and its integrated solutions and reporting can be customized for any customer function or management need.