About AAR Circular Letters

Circular letter summaries are produced monthly by Greenbrier’s Regulatory Management team, a division of Greenbrier Management Services Group.

AAR circular letters provide information of general applicability to the railroad industry, including proposed and final rules, revisions, standards and recommended practices, and calls for comments. These summaries provide the main points of circular letters issued in the prior month, as well as important implementation deadlines.

For access to the complete circular letter, please go to my.aar.org/circulars. Circular letters are a fee-based service provided by the AAR’s Transportation Technology Center Incorporated (TTCI). You may subscribe online at publications@aar.com or call 719.584.0538.

Implementation Circulars

C-13515

Implementation of Revisions to AAR Intermodal Interchange Rules, Section F, Section H, Section L, and Section M, Tires Slid Flat, and Repair Limit Increase

Issued: March 10, 2020

Effective: March 10, 2020

The implementation of the revisions to Section F, Section H, Section L, and Section M of the AAR Intermodal Interchange Rules, is now implemented and effective immediately. The revision clarifies when repair or replacement of tires with flat spots is needed, as well as an increase of the repair limit (from $450 to $750). The revision is attached to the circular, please update your library and be governed accordingly.

C-13526

Implementation of Editorial Revisions to MSRP Section G, Wheels and Axles, M-101, Axle End Chamfer

Issued: March 30, 2020

Effective: March 30, 2020

The implementation of the revisions to M-101 is now implemented and effective immediately. The revision, attached to the circular, will be incorporated in the next issue of the Manual of Standards and Recommended Practices, Section G. Please update your library and be governed accordingly.

C-13525

Implementation of Revisions to MSRP Section H-II, ROLLER BEARING MANUAL, S-723, Secondhand Seal Wear Ring Parallel Requirement

Issued: March 30, 2020

Effective: March 30, 2020

The implementation of the revisions to S-723 is now implemented and effective immediately. A previous revision removed the visual inspection of seal wear rings, this revision has added back the visual inspection requirements. The revision, attached to the circular, will be incorporated in the next issue of the Manual of Standards and Recommended Practices, H-II. Please update your library and be governed accordingly.

C-13524

Implementation of Revisions to MSRP Section G, Wheels and Axles, M-107/M-208, and S-669, Wheel Design Evaluation, Shot Peening Coverage, and Wheel Design Approval Process

Issued: March 27, 2020

Effective: March 27, 2020

The implementation of the revisions to M-107/M-208 and S-669 is now implemented and effective immediately. The update includes the analytic evaluation in S-669, an update of shot peening surface coverage description from “greater than” to “minimum of,” and an update to the wheel design approval process. The revision, attached to the circular, will be incorporated in the next issue of the Manual of Standards and Recommended Practices, Section G. Please update your library and be governed accordingly.

C-13523

Implementation of Revisions to MSRP Section G-II, WHEEL AND AXLE MANUAL, RP-633, Axle W Dimension References and Axle K Dimension Update

Issued: March 27, 2020

Effective: March 27, 2020

The implementation of the revisions to RP-633 is now implemented and effective immediately. The update includes changes to the references for the Axle W dimension, removal of Fig. 4.76 Shop Status Code Explanation, and increase of the K dimension for Class F and Class K axles. The revision, attached to the circular, will be incorporated in the next issue of the Manual of Standards and Recommended Practices, Section G-II. Please update your library and be governed accordingly.

Call for Comment

C-13522

Solicitation of Comments for Revisions to MSRP Section G-II, WHEEL AND AXLE MANUAL, RP-631, MD-11 Reporting and Bearing External Inspection

Issued: March 27, 2020

Effective: 30 days for comment

The proposal concerns the completion of form MD-11 prior to completing the external inspection. The proposed revisions do not have costs associated with implementation. The proposal is attached to the circular.

Solicitation of Comments for Revisions to MSRP Section I, Intermodal Equipment Manual, M-998, RP-853, Trailer Skirt, and IBC Handle Requirement

Issued: March 26, 2020

Effective: 30 days for comment

The proposed changes define the requirements for trailer skirts and design of the IBC handle position. The revisions do not have costs associated with implementation. The proposal is attached to the circular.

Notice of Circulars

C-13513

AAR Research Review Postponed

Issued: March 4, 2020

Effective: June 23-24, 2020

Due to current and evolving public health concerns related to the COVID-19 virus, the 25th Annual AAR Research Review is being postponed until June 23-24, 2020.

Location:

Transportation Technology Center

55500 DOT Rd,

Pueblo, CO, 81001

C-13514

Subject: Cancelled – Town Hall on Early Warning System Rewrite and Car Repair Rates

Issued: March 10, 2020

Effective: TBD

Due to current and evolving public health concerns related to the COVID-19 virus, the Town Hall Meeting is being replaced by a webinar. Details will be communicated shortly via the Circular Letter System.

C-13516

Open Registration for AAR M-1003 Basic and Advanced Auditor Training Classes in Mexico

Issued: March 10, 2020

Effective: Full schedule included in circular

The Association of American Railroads (AAR) Quality Assurance Committee (QAC) has scheduled all the 2020 Auditor Training Classes in Mexico. New M-1003 2019 revisions and program enhancements have been implemented in the new training materials for both the Basic and Advanced Training classes. Full class descriptions, links and dates are included in the circular.

C-13517

Informational Circular, Car Repair Facility Labor Rate – Effective April 1, 2020

Issued: March 11, 2020

Effective: April 1, 2020

The Car Repair Facility Labor Rate, effective April 1, 2020 is $141.22. This represents a decrease of $0.02 from the calculation for January 1, 2020. Last year’s back pay for one small railroad’s carmen and machinists has now been spread over four quarters and was therefore removed. This caused the decrease in the Labor Rate. The change will be reflected in the April 1, 2020 release of the AAR Office Manual.

C-13518

All AAR inspections and audits are postponed

Issued: March 17, 2020

Effective: March 17, 2020

Due to current and evolving public health concerns related to the COVID-19 virus, the AAR has postponed all AAR inspections and audits:

- Quality Assurance M-1003.

- Tank Car M-1002, Mechanical Inspections.

- DPLS Quality Review.

- And other Technical Inspections and Audits.

Until further notice, AAR will not remove a facility’s certification due to the temporary suspension of audits. M-1003 certified facilities can continue to refer to the M-1003 online registry for certification status. The AAR will re-evaluate the situation weekly.

C-13519

Informational Circular, Canadian Car Repair Facility Labor Rate – Effective April 1, 2020

Issued: March 24, 2020

Effective: April 1, 2020

The Canadian Car Repair Facility Labor Rate, effective April 1, 2020 is $182.61 CAD. This represents a decrease of $0.06 CAD from the calculation for January 1, 2020. The currency conversion factor used to calculate the Health & Welfare portions of the January 1 Canadian Labor Rate was 1.3204. The currency conversion factor used to calculate the Health & Welfare portions of the April 1 Canadian Labor Rate is 1.3178. This caused the small decrease in the Canadian Labor Rate. The change will be reflected in the April 1, 2020 release of the Canadian Price Master.

CPC-1357

Tank Car Facility Certification Audits

Issued: March 17, 2020

Effective: March 17, 2020

Due to current and evolving public health concerns related to the COVID-19 virus, the AAR has postponed all AAR inspections and audits:

- Quality Assurance M-1003.

- Tank Car M-1002, Mechanical Inspections.

- DPLS Quality Review.

- And other Technical Inspections and Audits.

Until further notice, AAR will not remove a facility’s certification due to the temporary suspension of audits. M-1003 certified facilities can continue to refer to the M-1003 online registry for certification status. The AAR will re-evaluate the situation weekly.

CPC-1361

Notification to Industry on AAR M-1002 Tank Car Facility Registry

Issued: March 25, 2020

Effective: March 25, 2020

The live registry includes the facility name, city, state, QA Code/Station Stencil, M-1002/M-1003 expiration date, and M-1002 certification elements (activity codes, material groups, repair level capability, and service equipment category).Like the online public access of the AAR M-1003 registry under the AAR Quality Assurance Committee site, the M-1002 certification registry is accessible through the AAR Tank Car Committee site at: http://www.aar.com/standards/TankCarCommittee.html

Each facility has access to their specific status within their online profile. If the tank car facility obtains/maintains M-1002/M-1003 certification, they will appear in the M-1002 certification registry list after the facility’s 2020 audit report is processed.

C-13521

Updated Schedule and Registration Links for 2020 AAR M-1003 Basic Auditor, Advanced Auditor and Root Cause Analysis Training Classes

Issued: March 27, 2020

Effective: Full schedule included in circular

The Association of American Railroads (AAR) Quality Assurance Committee (QAC) has updated the schedule for the 2020 M1003 Quality Training Classes. New M-1003 2019 revisions and program enhancements have been implemented in the new training materials for both the Basic and Advanced Training classes. Root Cause Analysis training class materials have also been improved. Full class descriptions, links and dates are included in the circular.

CPC-1358

Notification to Industry of AAR M-1002 Exhibit B-2 form

Issued: March 25, 2020

Effective: March 25, 2020

Note from the AAR concerning the release of the Exhibit B-2 form:

- The Exhibit B-2 form is an internal AAR document and therefore AAR reserves the to change the Exhibit B-2 form as needed, without notification to industry and at any time.

- The Exhibit B-2 form was formulated based on demonstration capabilities under paragraph 3.6 of M-1002 Appendix B (published under CPC-1354).

- The Exhibit B-2 form is not an auditing checklist for M-1002 audits.

- The AAR BOE auditor will use both the M-1002 Exhibit B-2 form and the M-1003 QAPE for the tank car facility AAR M-1002/M-1003 on-site audits.

- The M-1002 Exhibit B-2 is in no way to be interpreted as modifying or superseding the requirements of US and Canadian regulations or the AAR interchange standards.

The Exhibit B-2 form is attached to the circular.

CPC-1359

Clarification to the use of approved AAR Form 4-2 and associated fittings arrangement drawings by C6 and C6r Certified Facilities (T91.39)

Issued: March 25, 2020

Effective: March 25, 2020

In accordance with M-1002 Appendix B, a tank car facility certified to activity code C6 or C6r can perform modifications to the tank car fittings arrangement provided that the facility receives the following from the equipment owner: An approved AAR Form 4-2 and the associated fittings arrangement drawings referenced on the Form 4-2.

For any precedent approved AAR Form 4-2 to be used in a fittings arrangement modification, the precedent AAR Form 4-2 and associated fittings arrangement drawing must clearly identify each approved piece of service equipment being replaced, and its approved position(s) on the arrangement.

Regardless of which approved AAR Form 4-2 and associated fittings arrangement is provided by the equipment owner to the certified C6 or C6r facility to use, all work performed is to be in accordance with AAR specifications, standards and rules; and federal regulations.

If the C6 or C6r certified facility does not receive from the equipment owner an approved AAR Form 4-2 and associated fittings arrangement drawing as outlined in this CPC, then the equipment owner must seek approval per Chapter 1 of M-1002 for the modification.

The CPC is attached to the circular.

CPC-1360

Notification to Industry on Availability of Fillable AAR M-1002 Exhibit B-1 and Exhibit B-3a form

Issued: March 25, 2020

Effective: March 25, 2020

The AAR has updated the M-1002 Exhibit B-1 and Exhibit B-3a. These updated forms reflect the final action published within CPC-1354. The forms are attached to the circular.

PHSMA Notice

Notice of Enforcement Policy Regarding Training Requirements

Issued: March 23, 2020

Effective: 90 days from the date of issuance

The US Department of Transportation Pipeline and Hazardous Materials Safety Administration (PHMSA) continues to monitor the effects that the COVID-19 outbreak is having on the transportation industry and supply-chain. As a result, PHMSA has temporarily halted enforcement actions against offerors and carriers that are unable to comply with some of the training requirements included in the Hazardous Materials Regulations (HMR, 49 CFR 171-180).

The Notice is limited to recurrent training requirements contained in 49 CFR 172.704 (c)(2) and does not apply to all other HMR obligations or applicable laws for hazardous materials offerors and carriers.

For more information, download the Enforcement Policy Notice Regarding Training Requirements here.

49 CFR 172.704 Training Requirements can be reviewed here.

Greenbrier’s response to COVID-19

As this challenging time continues, Greenbrier would like to provide an update on operations and our continued dedication to our customers, employees, and communities. As rail workers and contractors are designated “Essential Critical Infrastructure Workers”, Greenbrier’s manufacturing and repair facilities are fully operational. Our office teams are available as well, though most are working remotely. We encourage you to contact your Greenbrier representative if you have any questions or concerns—we are here for you.

For more information, visit our webpage that details Greenbrier’s response to COVID-19.

Greenbrier’s Regulatory Services Group

Peace of mind for your business.

The Regulatory Management Group, led by James Rader, provides regulatory, engineering, process consulting and advocacy support to the railcar repair industry and the petrochemical rail shipper community.

- ASNT Level III Subscription Services

- DOT Compliance Assessments (Corporate and Plant)

- DOT Hazardous Materials Training (Corporate and Plant)

- Expert Witness Services in Rail-Related Litigation

- Federal Government Claims Mitigation (e.g. FRA and PHMSA)

- Nondestructive Testing Programs

- Quality Assurance Program Development

- Regulatory Counsel and Policy Advocacy

- Railcar Repair Management (Design Review, Drawings, Engineering and AAR Approval Administration)

- Tank Car Reliability and Maintenance Programs (49 CFR Subpart F of Part 180)

- Tank Car Maintenance Data Collection and Reliability Performance Analysis

- Welding Program Development

For inquiries about these summaries or any of our services, please reach out to: regulatoryservices@gbrx.com

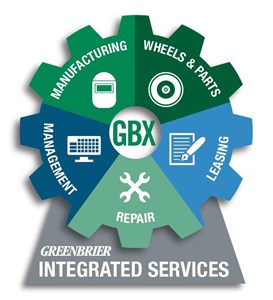

About Greenbrier Management Services (GMS)

Greenbrier Management Services (GMS) is North America’s most comprehensive railcar management solutions provider. GMS manages nearly 400,000 railcars and has invested over 20 years in developing technology, processes, and people to provide the best railcar management products and services in the industry. GMS is powered by proprietary software and the best subject matter experts in the railcar business.

COMPREHENSIVE. INTEGRATED. VALUE.

Combined, these two vitally important capabilities are able to deliver world-class solutions to every type of customer, from Class I railroads, lessors and industrial shippers to financial investors. GMS brings broad expertise to cover nearly any railcar management need that customers may have and its integrated solutions and reporting can be customized for any customer function or management need.