About AAR Circular Letters

Circular letter summaries are produced monthly by Greenbrier’s Regulatory Management team, a division of Greenbrier Management Services Group.

AAR circular letters provide information of general applicability to the railroad industry, including proposed and final rules, revisions, standards and recommended practices, and calls for comments. These summaries provide the main points of circular letters issued in the prior month, as well as important implementation deadlines.

For access to the complete circular letter, please go to my.aar.org/circulars. Circular letters are a fee-based service provided by the AAR’s Transportation Technology Center Incorporated (TTCI). You may subscribe online at publications@aar.com or call 719.584.0538.

Implementation Circulars

C-13643

Implementation of Revisions to MSRP Section C, CAR CONSTRUCTION FUNDAMENTALS AND DETAILS, Standard S-2056, Clearance Plate Diagrams for Interchange Service: New diagram, Plate N

Issued: September 3, 2020

Effective: September 3, 2020

Plate N is essentially a modified version of Plate F that includes one additional inch in height as well as more room in the upper corners of the diagram. In addition to Plate N, a new section 15.0 Plate Summary Table has been added to provide a list of dimensions of the various plates, rounded to the nearest inch, that are typically used for entrance into clearance software programs. Standard S-2056, attached to the circular, is now implemented and effective immediately. This modification will be incorporated in the next issue of the Manual of Standards and Recommended Practices, Section C. Please update your library and be governed accordingly.

C-13644

Implementation of Revisions to Appendix A of Section J, Specification for Quality Assurance M-1003

Issued: September 4, 2020

Effective: September 4, 2020

The following revisions have been approved for Appendix A of Section J

Locomotive Committee – remove:

- B55b – Reconditioner of Locomotive Radiators

Equipment Engineering Committee – update descriptions:

- B25 – Repair Shop (Facility)/Repair Track Engaged in Heavy Repairs

- B26 – Repair Shop (Facility)/Repair Track Engaged in Office Manual Rule 88.C Activity

Coupling System & Truck Casting Committee – technical requirement:

- Remove M-201 technical requirements from Activities A24 and B4

Wheels, Axles, Bearings & Lubrication Committee – update description:

- B33-2E Roller Bearing Cone Bore and Outer Ring Counterbore Plating

Tank Car Committee – revised to match B1 Table:

- Match Activities with B1 table of M-1002

The implementation of these revisions is effective immediately and will be included in the next edition of Section J, Specification for Quality Assurance M-1003. In the interim, please insert the Circular Letter attachment for Appendix A and be governed accordingly.

C-13645

Implementation of Revisions to MSRP Section S-III, COUPLER AND YOKE DETAILS, Standards S-176, S-177, S-178, S-179, and S-180, Regarding EOC Yokes

Issued: September 4, 2020

Effective: September 4, 2020

The purpose of this circular letter is to notify the industry of revisions to the following standards included in MSRP Section S-III, COUPLER AND YOKE DETAILS. Effective on January 1, 2021, new EOC yokes produced to these standards must be made from M-201 Grade E steel. The standards, attached to the circular, are implemented and effective immediately. These modifications will be incorporated in the next issue of the Manual of Standards and Recommended Practices, Section S-III. Please update your library and be governed accordingly.

C-13646

Implementation of Revisions to MSRP Section N, Specification M-951, Portable Bridge Plates for Multi-Level Auto Rack Cars

Issued: September 9, 2020

Effective: September 9, 2020

The Specially Equipped Freight Car Committee is implementing revisions to Specification M-951, Section 3.7 and Figure 3.2 and an Appendix B addition for Specifications on an Offset from Center Portable Bridge Plate. The addition to Section 3.7 and Figure 3.2 is to give an overhead view of nominal dimensions for standard bridge plates, and Appendix B is to provide requirements for an offset from center bridge plate. The changes to MSRP Section N, Specification M-970 are now implemented and effective immediately and will be incorporated in the next issue of MSRP Section N. In the interim, please insert the circular attachment into your copy of MSRP Section N and be governed accordingly.

C-13647

Implementation of Revisions to MSRP Section C, CAR CONSTRUCTION FUNDAMENTALS AND DETAILS, Standards S-226 and S-227 regarding design approval of running boards, end platforms, and brake steps

Issued: September 16, 2020

Effective: September 16, 2020

Tests that were being considered as a requirement for brake steps have been removed, as brake steps are not typically found on modern freight cars. Other requirements for brake steps were left in the Standard as guidance for replacement parts. Additionally, a reference to Rule 53 relative to approved end platforms has been removed from the standard until the approved list is implemented in the Rule at a future date. All other changes made to S-226 were editorial in nature. Standards S-226 and S-227, attached, are now implemented and effective immediately. This modification will be incorporated in the next issue of the Manual of Standards and Recommended Practices, Section C. Please update your library and be governed accordingly

C-13649

Implementation of Editorial Revisions to MSRP Section H, JOURNAL BEARINGS AND LUBRICATION, M-942 Appendix E, AAR-Approved Roller Bearing Grease and Seal Combinations – Update

Issued: September 17, 2020

Effective: September 17, 2020

Appendix E has been updated to include new conditionally approved grease and seal combinations. The revised Specification M-942, attached, is now implemented and effective immediately. This modification will be incorporated in the next issue of the Manual of Standards and Recommended Practices, Section H-II. Please update your library and be governed accordingly.

C-13648

Implementation of Revisions to MSRP Section G, WHEELS AND AXLES, M-107/M-208, and S-658, and MSRP Section G-II, WHEEL AND AXLE MANUAL, S-659, and RP-633, AAR-2A Standard Profile, AMFLEET Axle Relief Grooves, and Wheel Seat Measurement

Issued: September 17, 2020

Effective: September 17, 2020

M-107/M-208, S-669, S-658, and RP-633, attached to the circular, are now implemented and effective immediately. These modifications will be incorporated in the next issues of the Manual of Standards and Recommended Practices, Section G and Section G-II. Please update your library and be governed accordingly

C-13653

Implementation of Revised MSRP Section C, CAR CONSTRUCTION FUNDAMENTALS AND DETAILS, 2020

Issued: September 24, 2020

Effective: September 24, 2020

The revised MSRP Section C is now available in both printed and electronic versions. The manual can be purchased online at: www.aarpublications.com

All previously implemented standards and specifications are included in this print of Section C. Please update your library and be governed accordingly.

C-13654

Implementation of Revised MSRP Section G, WHEELS AND AXLES, 2020

Issued: September 29, 2020

Effective: September 29, 2020

The Association of American Railroads Wheels, Axles, Bearings, and Lubrication Committee (WABL) has released a new revision of the Manual of Standards and Recommended Practices, Section G, WHEELS AND AXLES. All previously implemented standards and specifications are included in this print of Section G. Please update your library and be governed accordingly. The manual can be purchased online at: www.aarpublications.com.

C-13655

AAR Manual of Standards and Recommended Practices (MSRP), Section K-I Railway Electronics Systems Architecture and Concepts of Operations, Standard S-9080.V2.0

Issued: September 30, 2020

Effective: September 30, 2020

Standard S-9080.V2.0, attached to the circular, defines policy-related items related to or required for PTC interoperability and associated document standard(s). Standard S-9080.V2.0 will be incorporated in the next issue of the MSRP, Section K-I Railway Electronics Systems Architecture and Concepts of Operations. In the interim, please insert the Circular in your copy of the MSRP Section K-I and be governed accordingly.

Call for Comment

C-13640

Solicitation of Comments for Revisions to MSRP Section S-III, COUPLER AND YOKE DETAILS, Standards S-108, S-109, S-155, S-165, S-170, and S-172, Standard E/F-Type Couplers

Issued: September 1, 2020

Effective: 30 days for comment

The proposed revisions make reduced slack E/F-type couplers standard and remove non-reduced slack couplers as standard. All AAR approved coupler manufacturers currently produce only couplers with reduced slack features. As a result, no costs to the industry are expected with these changes. The proposed standards are attached to the circular.

C-13639

Solicitation of Comments for Revisions to MSRP Section S-III, COUPLER AND YOKE DETAILS, Standards S-102, S-103, S-107, S-154, S-163, and S-164, Standard E-Type Couplers

Issued: September 1, 2020

Effective: 30 days for comment

The proposed revisions make reduced slack E-type couplers standard and remove non-reduced slack couplers as standard. All AAR approved coupler manufacturers currently produce only couplers with reduced slack features. As a result, no costs to the industry are expected with these changes. The proposed standards are attached to the circular.

C-13650

Solicitation of Comments for Revisions to MSRP Section H-II, ROLLER BEARING MANUAL, Standard S-723 Rule 3, Vented Backing Rings and Maintenance Specifications

Issued: September 17, 2020

Effective: 30 days for comment

The proposal, attached to the circular, includes the following changes:

- Vented backing rings may not be returned to service.

- The bearing maintenance specifications have been updated.

The proposed removal of vented backing rings has a maximum one-year industry cost of $3.6 million and 15-year net present cost of $18.2 million. These costs are below the thresholds prescribed in AAR Standard S-050.

C-13651

Solicitation of Comments for Revisions to MSRP Section H, JOURNAL BEARINGS AND LUBRICATION, M-934 and S-703: Bearing Placement Requirement, Inner Ring (Cone) Marking, and Freight Cap Screws

Issued: September 17, 2020

Effective: 30 days for comment

The proposal, attached to the circular, includes the following changes:

M-934, Freight Car Journal Roller Bearings

- Update to the bearing placement requirement during conditional approval.

- Addition of inner ring (cone) marking requirement.

S-703, Cap Screws for Journal Roller Bearing Assemblies

- Removal of all non-interchange cap screws from the table.

The proposed revisions to M-934 and S-703 do not have costs associated with implementation.

C-13652

DRAFT Standard S-9080.V2.0 – Positive Train Control Interoperability Committee Policy, is available for review and comment. In support of AAR’s MSRP, Section K-I, Railway Electronics Systems Architecture and Concepts of Operations

Issued: September 18, 2020

Effective: 7-days for comment

This document describes policy-related items related to or required for PTC interoperability and document standard(s) associated with each. The list of policies and associated standards shall be under the governance of the PTC Interoperability Committee. Comments regarding the DRAFT may be submitted to submitcomment@aar.org or by using the Comment Form found on the SharePoint site. The DRAFT document and the Comment Form can be found at:

Notice of Circulars

C-13642

Informational Circular, Canadian Car Repair Facility Labor Rate – Effective October 1, 2020

Issued: September 2, 2020

Effective: October 1, 2020

The Canadian Car Repair Facility Labor Rate, effective October 1, 2020 is $182.26 CAD. This represents a decrease of 1.24% ($2.29 CAD) from the calculation for July 1, 2020.

C-13641

Informational Circular, Car Repair Facility Labor Rate – Effective October 1, 2020

Issued: September 2, 2020

Effective: October 1, 2020

The Car Repair Facility Labor Rate, effective October 1, 2020 is $138.05. This represents a decrease of 2.1% ($2.95) from the calculation for July 1, 2020.

Greenbrier’s response to COVID-19

As this challenging time continues, Greenbrier would like to provide an update on operations and our continued dedication to our customers, employees, and communities. As rail workers and contractors are designated “Essential Critical Infrastructure Workers”, Greenbrier’s manufacturing and repair facilities are fully operational. Our office teams are available as well, though most are working remotely. We encourage you to contact your Greenbrier representative if you have any questions or concerns—we are here for you.

For more information, visit our webpage that details Greenbrier’s response to COVID-19.

Greenbrier’s Regulatory Services Group

Peace of mind for your business.

The Regulatory Management Group, led by James Rader, provides regulatory, engineering, process consulting and advocacy support to the railcar repair industry and the petrochemical rail shipper community.

- ASNT Level III Subscription Services

- DOT Compliance Assessments (Corporate and Plant)

- DOT Hazardous Materials Training (Corporate and Plant)

- Expert Witness Services in Rail-Related Litigation

- Federal Government Claims Mitigation (e.g. FRA and PHMSA)

- Nondestructive Testing Programs

- Quality Assurance Program Development

- Regulatory Counsel and Policy Advocacy

- Railcar Repair Management (Design Review, Drawings, Engineering and AAR Approval Administration)

- Tank Car Reliability and Maintenance Programs (49 CFR Subpart F of Part 180)

- Tank Car Maintenance Data Collection and Reliability Performance Analysis

- Welding Program Development

For inquiries about these summaries or any of our services, please reach out to: regulatoryservices@gbrx.com

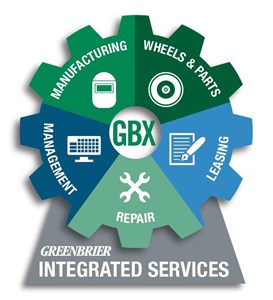

About Greenbrier Management Services (GMS)

Greenbrier Management Services (GMS) is North America’s most comprehensive railcar management solutions provider. GMS manages nearly 400,000 railcars and has invested over 20 years in developing technology, processes, and people to provide the best railcar management products and services in the industry. GMS is powered by proprietary software and the best subject matter experts in the railcar business.

COMPREHENSIVE. INTEGRATED. VALUE.

Combined, these two vitally important capabilities are able to deliver world-class solutions to every type of customer, from Class I railroads, lessors and industrial shippers to financial investors. GMS brings broad expertise to cover nearly any railcar management need that customers may have and its integrated solutions and reporting can be customized for any customer function or management need.